From The Telegraph

Britain’s wind farms are wearing out far more rapidly than previously thought, making them more expensive as a result, according to an authoritative new study.

By Robert Mendick, Chief Reporter

8:40AM GMT 30 Dec 2012

The analysis of almost 3,000 onshore wind turbines — the biggest study of its kind —warns that they will continue to generate electricity effectively for just 12 to 15 years.

The wind energy industry and the Government base all their calculations on turbines enjoying a lifespan of 20 to 25 years.

The study estimates that routine wear and tear will more than double the cost of electricity being produced by wind farms in the next decade.

Older turbines will need to be replaced more quickly than the industry estimates while many more will need to be built onshore if the Government is to meet renewable energy targets by 2020.

The extra cost is likely to be passed on to households, which already pay about £1 billion a year in a consumer subsidy that is added to electricity bills.

The report concludes that a wind turbine will typically generate more than twice as much electricity in its first year than when it is 15 years old.

The report’s author, Prof Gordon Hughes, an economist at Edinburgh University and a former energy adviser to the World Bank, discovered that the “load factor” — the efficiency rating of a turbine based on the percentage of electricity it actually produces compared with its theoretical maximum — is reduced from 24 per cent in the first 12 months of operation to just 11 per cent after 15 years.

The decline in the output of offshore wind farms, based on a study of Danish wind farms, appears even more dramatic. The load factor for turbines built on platforms in the sea is reduced from 39 per cent to 15 per cent after 10 years.

Prof Hughes said in his conclusion: “Adjusted for age and wind availability, the overall performance of wind farms in the UK has deteriorated markedly since the beginning of the century.

“In addition, larger wind farms have systematically worse performance than smaller wind farms.”

The study also looked at onshore turbines in Denmark and discovered that their decline was much less dramatic even though its wind farms tended to be older.

Prof Hughes said that may be due to Danish turbines being smaller than British ones and possibly better maintained.

He said: “I strongly believe the bigger turbines are proving more difficult to manage and more likely to interfere with one another.

“British turbines have got bigger and wind farms have got bigger and they are creating turbulence which puts more stress on them.

“It is this stress that causes the breakdowns and maintenance requirements that is underlying the problem in performance that I have been seeing.”

Prof Hughes examined the output of 282 wind farms —about 3,000 turbines in total — in the UK and a further 823 onshore wind farms and 30 offshore wind farms in Denmark.

The report, published last week by the Renewable Energy Foundation (REF), a think tank that has campaigned against wind farms, will give ammunition to sceptics, especially within the Conservative Party, who believe the cost of subsidies to the wind industry is far too high and that the growing number of turbines are blighting the countryside.

Dr John Constable, the director of REF, said: “This study confirms suspicions that decades of generous subsidies to the wind industry have failed to encourage the innovation needed to make the sector competitive.

“Bluntly, wind turbines onshore and offshore still cost too much and wear out far too quickly to offer the developing world a realistic alternative to coal.”

HT/Alan Tomalty

The turbines interfere with each other.?

Is this low frequency vibration?

How far is this vibration effective?

This might cause a headache for some people.

Just askin?

Low frequencies in the atmosphere propagate to distances of many miles, although we can not hear them, the vibrations may be sensed by our bodies, so don’t be surprised if your bones rattle a bit if you live within 5-10 miles of a large farm. On positive side the effect may reduce some of the excessive body fat.

Might it have a positive effect on bones?

It positively may reduce excessive bones as well.

Ferd…thank you for the laugh

If you know of an old graveyard in vicinity of a wind farm don’t go anywhere near after dark 🙂

On the negative side, infrasound is harmful to the brain

That might explain the apparent increase of whacky people in this world.

icisil December 29, 2018 at 7:15 am

On the negative side, infrasound is harmful to the brain

———————

have you proof of this you would like to share. I thought infrasound has proved useless as a weapon or as crowd control.

Turbines that are downwind of other turbines receive significantly less and less effective wind,

(due to swirling) that I know.

Down stream turbulence puts very high impact type stresses on the machines in the wind shadow. On water, (sailing) the wind shadow is 300 times the height of the disturbance. This is not unlike trailing vortexes from landing aircraft. Also, wind speed is less at the ground than at the top of the blade pass. This results in more oscillating input.

I designed many dynamometer test and break in facilities for the gear boxes used to speed up the input from the primary shaft. The gear box is the Achilles Heal of these things. They are under designed with low service factors like aircraft but are not maintained with the same vigor. They are designed to be cheap. The typical design has the main shaft (16 to 30 inches diameter) supported on a large, self aligning, radial/thrust bearing. The extension of this shaft has the low speed input to the gearbox rigidly mounted on it so the gear box is shaft mounted. The large bearings of the low speed input and the case of the gearbox then take all of the side loads resulting from the turbine blades. Two large pins in the extreme extent on opposite sides of the case are mounted in rubber lined bases. They react the torque and side loads. Speed up ratio increases the typical 14 to 20 rpm turbine to synchronous speed for the generator. Typical gear boxes have a planetary low speed input followed by two stages of helical gear speed up.

Mean time to failure of the gear box varies with maintenance. A few years ago, this was 6 to 18 months. I doubt it has improved much. Rebuild costs are in the hundreds of thousands each. A projected 30 years life is disengenuously stupid and known to be false. One needs to understand the money metrics. Legislation typically requires an installed base of some percentage renewables. Bargain basement low bid turbines are the lowest per rated output. The rules typically do not require that the devices are working to claim credits. The amortized cost is assessed to the rate payers bills even if the turbines are broken. The power sellers make more money when the things are broken. There have been massive subsidies in cash and tax rebates as well.

Mark:

Interesting information. What’s involved in a gearbox rebuild? Does the whole nacelle have to be craned down to ground level, or can it be rebuilt in place?

H any machinery to remove the gearbox. The input low speed shaft is hollow and mounted directly on the wind turbine shaft. It is retained by a B-Lock compression disk or equivalent. Pretty standard long shaft coupling to the generator shaft at the high speed end. Remove the high speed coupling. Loosen the B-Lock. Remove the caps to the pin retaining bases. Slide the gear box off the low speed coupling. The box weighs 50,000 to 80,000 pounds. Big crane used to swap out a rebuilt box. When you pass a wind farm and see turbines not spinning they are probably broken. Since I rarely see service cranes I suspect they do several at a time. I’ve not been involved in the field work.

Gear box damage can be failed bearings, broken teeth all the way to the housing broken to pieces. Some is rebuildable and some is scrap iron. The rebuild is new gears, bearings. Careful assembly with progressive load testing, oil analysis, cooler testing, vibration analysis. Final run in to burnish the gear teeth. Open port inspections. No guarantees. Some facilities are well run. Some are good ole’ boys with wrenches. All rely on subsidies and tax discounts. None of these facilities are built before the various support funding is lined up.

I’m a little familiar with helicopter transmissions. I know that quite a bit of electricity is used up to do run up testing of new and rebuilt transmissions. Is that also the case for wind turbine gearboxes?

Enercon bypasses this with NO gearbox. What you see IS the total machine. Germany is far ahead of the US

Amazing. So far ahead of us and they still don’t work sufficiently to avoid using brown coal.

So far ahead at triple the price. How amazing.

BigT: Indeed, Germany has long surpassed US in 18th Century tech. Gives us SUCH an inferiority complex, we have to try harder. Oh, and we seem to have better bs meters than Germans.

So how does the power transmission work? Variable speed drive?

Variable Frequency Drive in more recent wind turbines.

A 2MW wind turbine was installed as part of a project I was participating in. (I.e. the project consisted of many contracts, I was working on “Contract 4” and it was part of “Contract 10” – or something like that.)

Once it finally got going, it was clear that its speed of rotation was highly variable. So how were they able to maintain a constant 50 Hz onto the grid?

But not being an electrical engineer, I posed the question to someone who was both an electrical engineer and involved on wind-turbine contract. His explanation (in over-simplified lay terms for my benefit) was that the variable frequency AC from the wind turbine was first rectified into DC and then somehow converted back into AC at the correct frequency.

AC – DC, then DC – AC with huge losses in the form of heat.

rah December 29, 2018 at 8:58 am

So how does the power transmission work? Variable speed drive?

—————————–

Electronics is the way

https://www.enercon.de/fileadmin/Redakteur/Medien-Portal/broschueren/pdf/en/ENERCON_TuS_en_06_2015.pdf

The uk – france interlink is dc across channel and 50Hz conversion at either end. Power conversion of 2GW is reliable

Read many sales brochures, Big T?

Most large wind turbines sold today do not have gearboxes.

Rotor and stator, NO gear box, DUH!

Big T’s argument seems to be “My sh1t sandwich is better than yours!!”

He could be right, but now he has to find somebody who’s really paying for all this (ie NOT A GOVERNMENTAL WEENIE) who really cares.

Bit T could be going 0 for 2.

No gears, but they still have a shaft with all of the bearing problems that were listed above.

I’m sure I’ve read on these pages that due to the structure of subsidies provided to German wind farms, they tend to use larger turbines that are then digitally regulated to keep production below a certain level. This means that they stay nearer to their plated capacity for more of the time. It presumably means that as the turbines deteriorate over time, there is also the option to squeeze more generation out of the turbine.

Strongly agree with your comments. While in the Navy I worked on the propeller shaft for the ships I served on. These shafts were designed to transfer the thrust created by pushing the ship in a way that prevented any misalignment of the turbine reduction gears needed to reduce the speed of the turbine down from thousands of RPM to less than a hundred RPM needed for the propeller. Displacement, vertically, [horizontally] or axially of less than the thickness of a thin sheet of paper would be a disaster. Proper lubrication was essential and maintenance, including cleanliness of the lubricant was of utmost importance. The lube oil system was cleaned with a centrifugal oil cleaning system weekly. The cleaning system even included an extremely strong magnet to help collect metallic particles.

For many years, changing the 85 gallons of gear oil was done in a ‘bucket brigade’ fashion wherein one man atop the nacelle would scoop out the fluid and lower it down to a companion on the ground who dumped it in a container.

A 12 man hour process.

Some enterprising service companies came up with a trailer mounted suction type process to expedite the procedure.

One big factor in poor performance of many older units was that it was impossible to 100% remove all the old oil.

For interest look up HMCS Kootenay gear box explosion. Gearbox failed during a full power run in the English channel, 9 killed, 7 in the engine room.

It turned into a story about heroism and professionalism. link

It has also been said that bearings are the Achilles Heel of wind turbines. link

Turbine blades are heavy and they also represent a long lever. As well, they face unpredictable loading. The loading on the bearings is truly nasty. One of the loads you wouldn’t suspect results when the turbine isn’t moving. Brinelling happens when the elastic limit of the bearing material is exceeded. Turbines have to be kept moving even when there’s no wind to prevent this.

Unfortunately, moving parts are the bane of any mechanical system. (and I’m an ME)

Depending on assembly and installation, the bearings can see a great bit of damage from transportation while not moving. Repeated shock loads on the same locations will cause significant bearing damage before the bearings even get put into use.

Years ago I worked on a system to recover sick/injured astronauts from the ISS (International Space Station) and have them safely in a terrestrial hospital in under 12 hours. The forces during reentry were rather difficult to maintain below required limits (for astronaut safety) but achievable. As a bit of an aside we conducted g-loading measurements on a patient in an ambulance ride (vertical/lateral) and found the loads on the patient in an ambulance ride were 5 times larger than those imposed upon the re-entry vehicle including touch down!

Seems rather poor system requirements allocation to survive reentry and landing only to be killed by the EMTs on the way to the hospital.

You would think the person writing the specifications would have analyzed the forces a patient received in the typical ambulance.

Only had one ride in one – broken leg . Was definitely a ride I did not want to take ever again. Felt like I was riding on a sheet of steel, in a military Jeep. Worse than any Amusement park ride.

I remember watching a water ambulance in Venice under lights and sirens and thinking that it would have been the worst ride with any sort of broken bone.

You are right about brinelling Bob. A my steel plant there is a preventative work order to have a person give each stored spare electric motor and gearbox shaft a turn every month. There is a lot of heavy objects shaking the ground and we were getting a lot of very early bearing failures. We started doing this back in the 80’s and made a big improvement.

Standard specifications at Dow Chemical in the 1950’s

https://wattsupwiththat.com/2014/08/26/bearings-the-achilles-heel-of-wind-turbines/

https://onyxinsight.com/wind-turbine-failures-encyclopedia/bearing-failures/brinelling/

https://www.aerotorque.com/sites/default/files/10-BN-Magazine-February-2015-issue%20-%20AeroTorque%20Article.pdf

http://www.powertransmission.com/issues/1014/Premature_Bearing_Failures_PTE1014.pdf

What else would you expect when you hang huge vertical weight right at the end of a horizontal shaft?

The design is inherently compromised because mounting the blades horizontally on top of the tower is not feasible. Chelmsford flower mill abandoned wind power to mill flour in 1836 for coal. It was a stupid idea in 1836 to generate power from the wind and it is stupid now. But without wind and solar green would have to abandon its pseudo scientific hobgoblin agenda. The whole green edifice would tumble down if they were unable to suggest an alternative source of energy to fossil fuels and nuclear.

Wind and solar only exist to promote the myth that civilisation can survive without fossil fuels and nuclear. What is never discussed is that without the portability of oil wind and solar farms are not possible because they rely 100% on the availability and abundance of coal oil and gas. No oil no nothing. You cannot dig stuff out of the ground without the portability of oil. Indisputable fact.

Well, there were coal-powered steam shovels ‘in the day’ but I for one don’t want to back…

Nice info, Mark.

They are under designed with low service factors like aircraft but are not maintained with the same vigor.

Yeah, the goal is to get them up & running (sometimes), then get outta Dodge.

My metric would have been to take the worst case estimates and cut them in half to be close to reality. I consider offshore windmills beyond ludicrous. If offshore gets better than 5 to 10 percent expected longevity I’d be surprised. The logistics and cost of sea maintenance means it’s not going to happen near enough. Though the windmills should make great fishing reefs when they go down.

Years of a beach front condo taught us to just by the cheapest air conditioning unit you could buy

Offshore is severe duty. Something there is that doesn’t love a chloride ion.

Solidified argon? Just keep it below 83°K.

I lost count of the number of offshore turbines that weren’t turning, alongside others that were, as we sailed the Baltic & North Sea coasts of Germany & Holland last year, but it was certainly in the hundreds.

It says the interference problem is turbulence which is chaotic motion, so I’d think that would not be a source of low frequency sound, at least not a consistent droning kind of noise.

I’m just speculating but these slow turning blades probably are most efficient when air is flowing past them in laminar flow. Current eddies form behind the obstruction to flow and if another windmill is in that space, it experiences turbulence which likely increases stresses on bearings and causes more wear.

Regardless of the “useful” life of the windmill, the bigger issue is intermittency. Proper sizing, siting, and bearing design might resolve the excessive wear issues, but what will solve the problem that wind power supply can’t follow demand?

When the wind ceases to blow, you turn the front row of windmills to face the rest of the field, switch them into reverse and power them up as fans to keep the rest of the turbines on the wind farm running.

Don’t laugh. Remember the lights used at night on the solar panels in Spain?

What you do is to site the windmills at an airport, so the steady stream of aircraft taking off will provide all the power you need. This solution has already been adopted for thermometers.

Has wind ever had a laminar flow? If it has, how long has it lasted?

The interference mentioned to probably refers to wake interference and turbulent flow impinging on down wind turbines.

Of course it is stress which causes failures. In mechanical systems, it is the ONLY thing that causes failures. Improper analyses and fatigue life calculations are to blame. Some of this is defined by “unknown unknowns” in that the interaction between adjacent turbines was inadequately estimated (obviously) and unwarranted ‘margins’ were reported.

This is to be expected from marketeers pushing unproven and untested systems. They ALWAYS overestimate the life expectancy and output from the systems they are hawking. They are salesmen!

What needs to be done now is acknowledgement of the true limitations of these systems (which we engineers have been shouting about for some time now). And… some really big backtracking on planned municipal failures.

“Of course it is stress which causes failures. In mechanical systems, it is the ONLY thing that causes failures.”

Well, not all mechanical engineers would agree with such a blanket statement. I’ll offer four counter-examples: 1) lack of lubrication can cause galling of metals, thereby lack of function (as in bearing seize-up failures), 2) parts can fail from simply overheating (as in pistons melting and burning through in race car engines), 3) corrosion (e.g., rust) can cause parts to loose critical clearance fits and bind-up, thereby ceasing to function properly, and perhaps most interestingly in context, 4) lack of proper bolt torque (LACK of developed bolt tensile stress) can cause failure of such fasteners under vibration loads.

Otherwise, you raise some good points.

Errrr . . . make that “. . . to lose critical clearance fits . . .” in 3) above. My bad.

Other considerations that cause failures are erosion, metallurgical changes such as embrittlement or lack of ductility

How is it that the engineers in Ontario approved of our government subsidizing these industrial scale turbines.

Don’t engineers take an oath?

Yes, they do. They can be held legally accountable for their decisions. However, given the politics surrounding the issue, it’s unlikely anyone will be brought to book on this. You pretty much have to kill someone for it to be actionable.

I really doubt that engineers were involved in the decision to subsidize. That is really a political matter.

I am very disappointed that engineers designed these machines from start to finish. It is very myopic to design and build such complex and expensive plant while ignoring the fact that the whole concept is not fit for purpose. None of these systems have output that matches customer load demand. They are really just virtue signalling toys which disrupt the grid.

I suppose this is an example of what professionals will do for money.

Wind turbine blades are airfoils that disturb the smooth flow of air when the extract energy from it and also create powerful vortices at their blade tips. The leave a wake behind them in the air similar to the wake of a boat in the water. The intermittent forces of turbulent air and especially the vortices are potentially very damaging to turbines that are downwind. The largest turbines need to be spaced a mile apart to avoid being damaged, and also to have a good probability of seeing wind that has not been disturbed by upwind turbines. Most wind farms are not built with sufficient spacing because of land cost, road cost, and power cable cost considerations. Developers and their engineers knew all this, and that the gearbox life would be 12-15 years rather than the 20-25 promised, but they were allowed to make false claims of performance to help politicians justify their schemes.

The discussion on bearings is interesting and relevant. The number of teeth on each gear and the number of blades can be used to predict the pattern of impact damage on the bearing races.

The major reason for the early failure of bearings is they are deliberately under-spec’d because one large enough absorbs so much energy, the economic viability is compromised. Given the low speeds perhaps large Vescanite sleeves should be considered with appropriate hot oil.

Turbines without gears like the one at the CNE in Toronto avoid the whole problem but the complexity on the electrical side is an issue.

In answer to the question about phase synchronization, that is managed by using a line sensor to pick up the grid phase angle, and electronics to put power into the grid in phase at a slightly higher voltage.

The reason wind turbines cannot be momentarily disconnected then reconnected is because each generator has to first sense the line before connecting. I understand that if a set of turbines cannot operate on their own – they have to have a stable grid to which it can connect. I also understand that the South Australia blackout was as long as it was, because of the time needed to get the wind sources connected one by one.

An interesting point. They are currently installing the cables locally to me for a new bigger wind farm in the North Sea. Because of, especially, the undersea cable length it will be DC transmission at +/- 300kV. I’m assuming the offshore stuff will be AC because of the need to go up to hundreds of kV before rectification, so your comment prompted the thought of how to get a ‘stiff’ enough AC reference offshore to bring up the turbines against. Plenty of scope for runaway instabilities as the various turbines fight each other…

A good visual example of the vortice effect can be seen in this picture:

https://www.flickr.com/photos/vattenfall/4270899001/

Dr. Bruce Rapley has done significant work on the subject of arrays of turbines that in some cases surround homes. Sound waves collide and amplify harm.

https://stopthesethings.com/2015/07/09/dr-bruce-rapley-tells-senate-wind-farm-nocebo-story-nefarious-pseudoscience-an-insult-to-intelligence/

Two bob: as the wind passes through the turbine blades, it gives up some of its kinetic energy (velocity) in the process, it has to expand in volume in order for the mass flow to be equal on both sides of the blades. This causes a wind “shadow” which interferes with the downwind turbines.

I have several of these giants near my place, and I can assure you the noise from them is clearly audible through thick double glazing.

Thanks to my audio engineering work I have recorded them with studio microphones.

I would be more than happy to supply you with a spectral analysis and FFT.

There’s quite a lot of frequencies in the mix.

The most annoying ones by far are those caused by turbulence on the blade edges, which has frequency components across most of the audio spectrum.

I don’t doubt these worsen as the whole assembly ages.

To be able to produce the huge low frequency energy of the size they do, means the blades themselves must have severe eddy and cavitation issues, generating large pressure spikes which clearly vary related to blade velocity and wind offset direction (they never align perfectly with air flow for the reason below).

I would suggest, most of the problems relate to the fact the offset of the blade and pitch to the airflow direction is constantly varying. The leading blade exceeding the air flow velocity while a trailing one is dragging below the airflow velocity.

This is a well known problem for helicopter blades, which as we know represent a monumental noise pollution problem in and around cities.

It limits their forward flying speed to a point where the forward moving blade approached a critical mach number, while the reverse motion blade is actually decreasing the general efficiency of the whole.

I can’t think of a much more inefficient way to try to generate or capture power than to have in effect the reverse system of a helicopter assembly.

It simply cannot work, and it certainly cannot operate silently and without generating huge stresses in the entire structure.

This economist’s (not an engineer) data don’t agree with data collected by the US Department of Energy which confirms that the average load factor for installed wind turbines in the US is 43%, with the newer turbines at around 50%.

Perhaps the UK wind turbines are affected by the relatively wet salt air of the Atlantic, which an engineer would understand tends to increase corrosion and friction wear in generator bearings. The vast majority of wind turbines in the US are located in the dry southern Great Plains.

Determining the actual performance and factors affecting them is not the job description of an economist – only engineers can do that. Relying on this report generated by an economist is like relying on the typical government weenie with a degree in poly sci for the final word on climate change.

Numbers don’t lie, only liberals… : )

Try this link

https://www.ref.org.uk/generators/index.php

I have checked a number (not many) and see no decline in load factor.

The referenced document https://www.ref.org.uk/attachments/article/280/ref.hughes.19.12.12.pdf is interesting in that all it says for plots is “Source: Author’s estimates.” I too could write a document showing a 50% increase in load factor by using my warped estimates!!

It is also interesting that 2012 is latest data!

interesting discussion

https://www.carboncommentary.com/blog/2014/01/05/response-from-professor-gordon-hughes-to-previous-posting

When are the engineers going to duplicate his study?

Or, why would any engineer carry out a study like this? If they had, you might say that an engineer is not qualified for this type of research. Engineers are trained to design and build things, not to do this sort of study, for which they have no special training.

And, of course, I am going to believe US govt paid bureaucrats. Can you tell me which highly qualified engineers gathered the data for the US Dept of Energy and which highly qualified people in the Dept of Energy wrote the report? BTW, that dept was established after the oil shocks of the 1970’s to help achieve US energy independence from Arab oil. How well has that dept carried out is mandate? Jimmy Carter also started the Dept of Education. That of course was just to help him get elected. How has that dept helped education in the USA?

Point is, this throwing out of data because you don’t like the guy who gathered the data is not very objective. And, invoking the name of a US agency as a claim to authenticity is ludicrous.

Well, I hope that some qualified engineers will get to examine his data and publish their own conclusions.

Joel, I would tend to believe the report of a professional engineer over the report of a bureaucrat. Engineers get sued when they are wrong, and lose their license to practice if their calculations proveably aren’t right. Plus if the report is done by a sizeable engineering firm, it has been reviewed by several people also having their careers at stake. Not that they can’t be occasionally be swayed by a customer who says he won’t pay their bill unless the report says what he wants.

Reliability, availability and maintainability are important parts of any systems engineering process.

This is decidedly false. Analysis for Engineering Economy is part of the training for every engineer. It make up a substantial part of the professional engineering exam in the US. Or did when I took that test.

I was able to skip around those in the exam, but I can’t in my real-life job. I can (usually) design the perfect solution to any problem. The real question is, the test of my effectiveness, is the customer willing to pay for my solution? If they’re not will to pay for my solution, that is the equipment and installation a designed, they’re not willing to pay me for my design, either, and I don’t eat.

My job for the last 25 years had been Energy Engineering for Buildings, and everything I do I have to present a Life Cycle Cost Analysis, with all proposed savings discounted back to Net Present Value, and then able to boil that down into a single, or at most two bottom-line numbers such as simple-payback, or Return on Investment, or whatever way is of most interest to my client.

In short, while the name on the study is that of an economist, I would venture to say there could be several engineers in his employment.

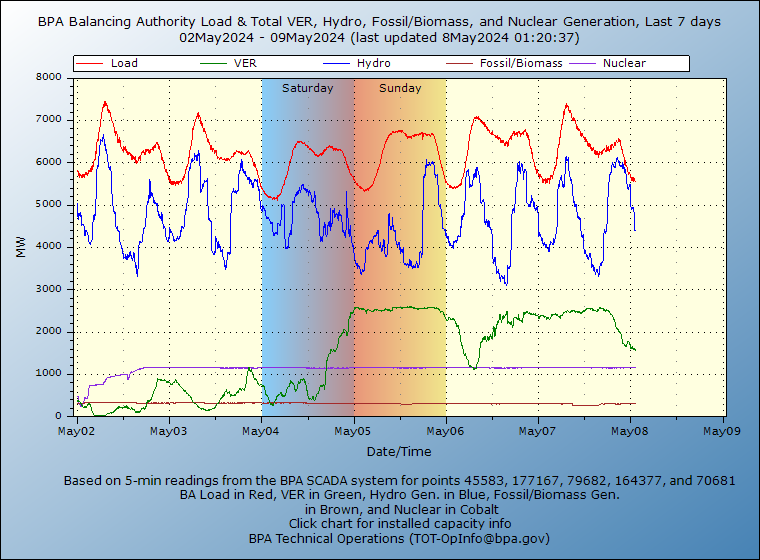

Your comments do not agree with BPA Balancing Authority Load and Total Wind, Hydro, Fossil/Biomass, and Nuclear Generation, Near-Real-Time – https://transmission.bpa.gov/business/operations/wind/baltwg.aspx

I have never seen a monthly average over 30% of Name Plate capacity.

BPA – Bonneville Power Authority has YEARS of data contrary to your assertion. Browse the pages and get enlightened.

Duane,

The latest EIA report indicates the capacity factor for the fleet of wind turbines was 33.7. https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_6_07_b

One can track plant level data at the EIA. I have been watching how Crescent Dunes has been performing over the months/years here-

https://www.eia.gov/electricity/data/browser/#/plant/57073

How many wind turbines, CSP and PV plants will it take to replace the output of Diablo Canyon in the dead of winter……

“How many wind turbines, CSP and PV plants will it take to replace the output of Diablo Canyon in the dead of winter……”

That’s a trick question. An infinite number of wind and solar arrays will not produce power during a windless night. Some storage is possible, as Diablo Canyon is near enough to the Castaic lake – Pyramid lake storage facility.

Dan,

I concur a new paradigm for balancing load during still winter nights is going to be needed. Steve Huntoon’s notes the importance of flexible demand in the Jacobson plan-

“Flexible Electric Demand. In order for the intermittent WWS resources to “work,” the Jacobson Group assumes 63% of industrial demand is flexible (totally controllable by system operators within eight-hour windows).”

https://www.rtoinsider.com/global-warming-renewable-power-47368/

135 miles as the crow flies through very rough terrain is not what I would consider optimal for pumped storage. The best storage is a large loop of thorium fluoride salt generating heat in a nice, controlled fashion.

Duane, Katoka,

From page 19, the way I am interpreting it, the eia capacity factors are based on available online time. When units are down for any reason they are not included in the calculation.

I may be wrong on this, but that’s the way I read it.

An economist that thinks the load factor of a wind turbine is 43% or 50% needs to go outside more.

Capacity factor is easy to rig. Simply reduce the peak output of the turbine artificially.

This will mathematically make the CF appear much higher, because CF = avg/peak. Just the sort of “trick” that made climate science famous.

Duane, you can be sure that an engineer was in attendance for such technical inspections. Social scientists aren’t competent to do this work. Given the engineering factors, yeah an economist could analyze this. You are too used to philiosophy profs, social psyche, political scientists … branding rhemselves as climate specialists.

Who didn’t see this coming ? LOL

anyone that lives under a rock.

Seriously.

It’s a machine. Did nobody think of how it was going to be repaired? (the nobody in this scenario are the people pushing for installations and collecting checks).

What I don’t understand is this: Governments are made up of people. People. Yes, you could argue sheep…but there is always (always…being non-scientific) a dissenter, someone who thinks about things a bit more in a group of enthusiasts, someone who sees the flaws in whatever is being spieled, someone who also may or may not have the courage to speak up but acts in different ways. People are people, groups of people are still groups of people and you have this dynamic no matter where you are, it’s human. Now for the most part in a group of people where the dissenter is a person of influence–that group will stop and think about what that influence has to say. Either in the thick of it or not. My point is, where the HELL are the influential people during these discussions to spend more tax payer money on more snake oil without thinking of the COST later on.

Now there are many examples in history of cost benefit analysis gone to the extreme—but honestly, a little bit…never hurts. Wind turbines, solar power, solar highways…etc. FIND me the bean counter to talk to–the person that is sitting in the room looking at the balance sheet. I want to go talk to that person, the one that has a ledger filled with variable costs and analysis. Lets hear from them. Because in the end, it doesn’t matter what the idea is–all that really matters is the bottom line….and I don’t mean the blue one, I mean the glaring RED LINE. Because I’ll bet you they know what it says.

Take that RED line to the influencer and then sit back and watch the snake oil salesman get run out on a rail.

Just a thought…….

So … we build these archaic contraptions in the MOST severe of planetary environments … and failed to predict a shorter service life for the machinery?

Perhaps “Big Oil” engineers who have designed oceangoing drilling platforms and horizontal drilling should have been consulted by the “green” energy intelligentsia

As a rule of rhumb, I at least cut predictions of climate factors, performance of renoobles, duration of effects, and aspects outside of climate science where livlihood depends on hype in half as a reasonable precaution. In the case of global avg temperatures, even with big thumbs on the scale, cutting in half then in half again would have given a more realistic prediction (alright, projection, but you know projections are even worse – you can’t get anyone to hang their hat on them).

Many years ago, I had an Indiana Jones type client into buying aluvial gold in Africa and melting it into doré bars for sale to a mint. He told his potential investors when they didn’t believe his astronomical expected profitability to call me to discuss it. They told me his projections topped out at IBM’s annual profitability. I told them to divide it by 1000 for a more reasonable figure and it was still a good investment. He got his investment funds. He called and thanked me for supporting him but was angry when I told him what I’d said. I told him he wouldnt have gotten it had I not.

Oops!

One wonders what kind of service/maintenance and life cycle contracts the turbines are under with the manufacturers.

On the lenient side I would hazard to guess.

NO subsidies are provided for maintenance (required in conventional plants at 12-15 months intervals, costing many hundreds of thousands of dollars for each shutdown period). Routine (expensive!) maintenance is mandatory, or builder’s warranties are voided.

And every tool and every new part has to be hand-carried up to the nacelle on ladders. Up 200 – 300 feet. By hand. Or you can rent a 400 foot crane – at $15,000.00 per day. That includes 2 days to set the crane up, two days to use it, and one day to tear it down and move it to the next nacelle. Every day is another day’s rental.

Subsidies and tax credits and tax write-off’s are ONLY provided for “nameplate” ratings at the construction, design, analysis (i.e., university/consultant/planning study money) phases. (Fabrication of assembly centers, for example, may get tax write-offs or exemptions, but repair centers and repair budgets come out of the owner’s operating budget. Which is NOT subsidized, since only the electric purchse price is mandated. No operations = no money incoming.

Once the windmills are built, maintenance is the first thing shorted. And, over a short period of time for new turbines, maintenance is not a priority. It can be deferred for a while. So short-term “operating historues are pretty good. Look at the operating facvtors for a turbine farm operating 10 years:

So where do they get the power to run the winch ? Can’t be from the turbine while it’s down for repairs.

The wind turbine is connected to the grid. Those engineers think of everything!

You’re going to need a bigger winch.

My sad attempts at humor aside, Steve’s probably right. I can’t see them attempting any kind of maintenance but the most basic clean and lube with just the equipment they can carry up themselves.

Makes me wonder if they each have a built in winch or what. They could bring one with them… but then they’d need a winch to lift the other winch up.

~¿~

So you could outfit the nacelle with a toolbox stocked with the basic items and an I.C. generator to run a convenience outlet, both already in place before lifting the thing to the top of that mast. But I don’t care how careful you stock the thing, at least 80% of the visits will have to call down, or maybe even send back into town, for something that wasn’t in the “basic” toolbox. There’s engineering, and then there’s real life. 🙂

In the US, the Federal subsidy for wind in based on the amount of power produced. (2.2 cents per kw-hr IIRC). If there is no power produced there is no subsidy. There is plenty of incentive to get that thing back into production.

The subsidy is only for the first ten years of operation.

I would keep a set of basic tools at the top of each turbine. I’d be surprised if no one else thought of that.

Increase both cost and weight. But what the heck, it’s only other people’s money.

But wait! No! We’ve been sold a CHEAP, clean, green, renewable energy future! Only a Luddite would wring their hands over the OLD way of doing things … like routine maintenance and repairs. Only a Luddite would speak of output degeneration! Only a Luddite wouldn’t believe in “magic”

In a related fable … the EPA certifies your Prius as obtaining 55mpg

Steve Heins December 29, 2018 at 8:22 am

I think this is more what you are thinking of.

remember the gear box, that thingy you need to move is 40,000-80,000 lbs.

Weight is an issue, as are focal points. trying to attach a wench to the turbine could destabilize it. And unlike Guam it can flip over.

https://www.sikorskyarchives.com/S-64_Product_History%20modX.php

michael

and hear that wenches really get upset when you try to attach them to turbines for some reason.

Oops,,,

More trash to recycle

And what about the damage to the aquifer from pile driving, especially in vulnerable terrain, during their construction and then the ongoing vibrations once they’re running?

https://www.cbc.ca/news/canada/windsor/water-wells-contaminated-ministry-environment-chatham-kent-turbines-1.4521473

Please site DOE reports indication operational load factors.

The important question is how long it takes for a wind turbine to generate enough electricity to make another wind turbine. After all, the power to create them has to come from somewhere.

If it doesn’t make a decent return on energy invested, say a factor of 8 or 9, then it is a useless technology.

Suppose it is 8:1. That means 1/8th of the entire energy system would be devoted to replacing wind turbines, in a wind powered economy. If the return was 2:1, then half the economy would be building such turbines. If the sheer brainlessness of that proposition is not clear, it will be soon enough as the resource wars escalate.

And the same logic applies to photovoltaics of course.

Not too long ago I completely ended an argument that way. A friend, oh let’s call him Kirk since that was his name and there’s no need to protect the innocent, started trying to tell me that one day soon all power will come from solar panels and we just wouldn’t have anything to worry about anymore. I said, “Kirk, if solar power was a good idea we would use solar power to build more solar installations.” Full stop. He said not another word to me about solar power. Ever. AFAICR.

Crispin in Waterloo December 29, 2018 at 6:56 am

The important question is how long it takes for a wind turbine to generate enough electricity to make another wind turbine.

I think you would see “the heat death of the universe” first.

michael

Yes, I am waiting for someone, anyone, to point out a photovoltaic or wind turbine manufacturer who uses their product to power their production facility. I can give many examples of gas, oil, coal, hydro, and nuclear plant producers who use their products to run their facilities.

The first nuclear power plants were used specifically to help in production of fissile materials for the bomb.

“The reasonable man adapts himself to the world; the unreasonable one persists in trying to adapt the world to himself.” George Bernard Shaw

Are you trying to be subtle? Not sure everyone will know that the rest of that quote is “Therefore all progress depends on the unreasonable man.”

But arguing that wind power is “unreasonable” but all progress comes from being unreasonable is nuts. It’s a fallacy to equate what is considered reasonable by social convention with what is possible to achieve through engineering.

Possible is one thing, cost effective is another. Sure, we engineers can eventually solve almost any problem. The question is, could that money be better spent elsewhere? Is it better to perfect the wind turbine or the breeder reactor for disposing of nuclear fuel? Is it better to perfect the ground-mounted solar panel or a space-based Solar Power Satellite?

yes exactly. When I said “possible to achieve”, I meant technically and economically feasible. Lots of innovations seem “unreasonable” to conventional thinkers until after they are achieved, which is I guess the “moral” of the GBS quote. But if the innovation is in fact not economically feasible, even though it is technically feasible, that is truly unreasonable and ultimately unsustainable.

I don’t quote George Bernard Shaw. He was a Socialist who believe in mass murder. https://www.youtube.com/watch?v=t3lBdyFvPps

He’s a true little monster actually.

indeed so.

Worse than that he was a major influence in the formation of Fabian socialism.

Fabians and Fabianism are still a major evil today as they are the guiding hand in most Western democracy’s so called ‘liberal’ political parties.

GTPath

That’s the sort of brainless nonsense you can expect from a Fabian.

This is the end of article. So, never mind if thing goes bad. Have faith and continue to pay and things will improve! The promise land is right there.

Notie that wind proponents have been claiming for years that wind power is getting cheap. Aside from

the fact that they usually omit realistic side effect costs ( or even acknowledge any side effect costs)

it can be pointed out using simple logic, that no one can estimate accurately the costs of wind power without knowing pretty accurately, the lifespan and maintenance costs of those turbines. Obviously turbines designed in past years had no history of such factors and therefore it is fraudulent to make any claims about the costs of the energy they produce. We know the lifespan of light water nuclear reactors and can estimate quite accurately the lifespan of a small modular molten salt reactor, since we know the deterioration rates of the sacrificial metals and have tested the deterioration in those cases of reactor cores where sacrificial metals are not employed. The electric generation steam turbines driven by the reactors,regardless of the type of reactor are also very well known from historical data, of which there is plenty , going back decades. We also know the cost of mainteance and cost of day to day operations. I believe we probably now have data as to the effects of age on solar panels, although the newer designs may or may not be the same.

When you skimp on basic maintenance, you can save money.

For awhile.

Wrote about this and much more in guest post True Cost of Wind some years ago at Climate Etc. The larger turbines suffer axial bearing failures from the inherent wobble caused by uneven loading with height. The true cost of US onshore wind is about $146/MWh, compared to CCGT at about $56.

The capacity factor is about 31% and the presumed life is 20years, which this study finds is overstated.

Rud: Your articles were informative and damning of the very idea of grid-level wind. IMHO, the early wear will be a good thing, ending a form of madness sooner rather than later. I seem to recall your articles brought out a few wind enthusiasts, wonder where they are now? Not commenting here.

Rud, does the $146/MWh include conventional backup power and incremental transmission costs?

This is a SIX year-old report from the DT. Has its findings/suspicions been proven? Just asking.

“The extra cost is likely to be passed on to households”

I always love this kind of statement – it should always read “the extra costs will be passed on to households”

There is no free lunch – ever.

Even if the government opts to pick up the tab or increase the subsidy – it will still be the taxpayer that bears the cost + all the inefficiencies and bureaucratic burden that goes with it.

Add in the “Great Stilling” and wind energy is nothing more than a puff of smoke…usually from fried bearings….

https://news.nationalgeographic.com/news/2010/01/101018-wind-power-farms-science-nature-geoscience-energy-environment/

September 13, 2018

The world’s largest wind farm was just completed in the Irish Sea — and it’s more than twice the size of Manhattan

“The Walney Extension opened last week with a generating capacity of 659 megawatts, and is located between northern England and the Isle of Man. Its 87 turbines, which stand up to 640 feet tall, are some of the world’s biggest in operation. The turbines, made by Siemens and MHI Vestas, each soar more than 600 feet in the air, more than twice the height of the Statue of Liberty.”

It is an impressive engineering achievement, many designers, engineers and transport people may not be entirely convinced in the economics of whole project but it was useful practical experience, it paid mortgages, school fees, etc; so who’s to complain , most of it is subsidised by taxpayers and electricity users for years to come, so let tax payers and energy consumers make the fuss about it.

https://www.businessinsider.com/largest-wind-farm-in-the-world-2018-9?r=US&IR=T

Why do I have the feeling that these monstrosities have very likely not been designed and constructed to withstand the storms that they will surely see before they have stood there for their design lifespan?

I would be surprised if they can even stand up to the corrosive environment of being surrounded by and sitting in salt water, for as long as they need to.

You are correct. They are designed to harvest subsidies.

Subsidies. Now here’s a thought. When Blair was in office he had (among others) two big problems: youth unemployment and education costs. He solved the problem by pushing 50% of the young into university – and then made them pay for it!

Then he had problems with AGW. Why not pay big friendly companies oodles of money to provide wind and solar power generation and build wind and solar farms. And make the public pay – even if they don’t think they are (they’re getting wise to it though!)

It comes down to politicians playing Bastiat’s broken window fallacy and hoping the proles don’t catch on – that it’s all a new way of taxing them while fooling them into believing the (generous) Government is providing for them.

When people really find out that all this wasted money could have been better spent on more efficient power generation – nothing will happen. we are sheeple, after all.

One of the problems with Blair’s strategy of sending over half the population of school leavers into further education was to produce a generation of endebted 20 year olds with qualifications no one wanted, but with aspirations to salaries they couldn’t command. Another issue was that there was a generation with no skilled artisans. A void filled by EU citizens arriving due to freedom of movement. The third problem was that universities and colleges needed courses and entry requirements that allowed less able students to meet the entry requirements. The net result is we now have a generation of politicians and scientists without the ability to think critically and to question analytically.

Ben, quite right.

You ask: “Why do I have the feeling that these monstrosities have very likely not been designed and constructed to withstand the storms that they will surely see before they have stood there for their design lifespan?”

Answer: So then the damage by the high seas can be blamed on Climate Change, and thus the excuse to build even more while clamping down even harder on those who must suffer under these conditions.

AWG: Good thinking – on AGW-caused damage. I have a feeling you will be right.

The turbines downwind (except for northers, etc.) from Corpus Christi, TX are also downwind from some of the saltiest waters in the Gulf of Mexico, especially so during droughts. Enough wind for sailboat races, close to the grid, but I did see some older ones that looked like they might have been leaking oil. They might work there as good as possible, but how high does the salt float? Another experiment, they seem to be reproducing somewhere, but require assembly.

And I suspect that their design will not have taken into account the “increasing severity of storms” predicted by “climate realists” as a consequence of AGW.

Wrong study, here’s the correct one from this year:

https://principia-scientific.org/new-study-could-spell-trouble-for-wind-energys-future/

And the end say:

So the ever-cynical me reads this and says, “No problem here. Charge the middle class more for ALL forms of energy, give many thousands in tax credits to low income energy users, particularly “immigrants” so that money can flow OUT of the country via repatriation. Win-Win.” In California this will be the reality by 2020.

A six year old story?

Did you read about this before now ?

Here’s a link to Gordon Hughes’ 2012 study:

https://www.ref.org.uk/attachments/article/280/ref.hughes.19.12.12.pdf

Molineux. Old does not mean wrong

Do you consider a 6 year old child ‘old’ and ‘outdated’?

In engineering of power machinery, field gathered 6 year old performance data is a large part of the basis data for the next generation design, if profitability supports. Your comment is uninformed and arrogant, truly ‘scraping the bottom of the barrel’ of credibility.

Once again, any excuse to ignore data that you don’t want to know.

It appears we have the climate realist version of “It is worse than we thought” right here.

This study is making the rounds:

https://dailycaller.com/2018/12/27/study-wind-power-declining/

Anyway, these are things with moving parts and anything with moving parts will eventually wear out, like my knees… 🙁

In general I would agree with you. However in the Ornamental Products division of my fathers business there is a hand built machine made for twisting 1/2″x1/2″ solid hot roll still bars for ornamental iron fence pickets and railings, etc. It was built by my uncle in about 1950 using a 1934 Dodge truck manual transmission hooked up to an electric motor and it still in use today. Pull up the lever to put the transmission in 1st gear and slam it down when you get the desired number of twists. To my knowledge it never has needed repair. I twisted 1,000s of bars on that thing as a kid and I would bet it has twisted well over a million by now. I’m beginning to think the thing is going to outlast me.

Yes, the huge lathes, drill presses, etc in the machine shop of the power plant I worked at were 1930 vintage (most were manufactured by Ingersoll Rand) and still worked fine in 2000. Replace the belts every now & then….

Still I hear NOTHING about the power needed to maintain, operate and control a wind turbine. Why do the Wind Turbine advocates, the EIA and environmentalists ignore that it takes power to make power?

A wind turbine requires power for the lubrication system, power for the control system, power for the anemometer to know which way the wind is blowing, power for the positioning system, power for the computers, power for the HVAC to keep the proper temperature and cool all of the electronic equipment, power to heat he lube oil system, power to cool the lube oil system, power for the hazard lights, power for the communications system, and a dozen other things I can’t think of now. Typical power requirements for generation systems are on the order of ten percent (10%) of the nameplate rated output. Read that again, ten percent, that is approaching a sizable amount of the total generated power. That power is needed 24/7/365/20 years. If the lube oil system is not running the blade can not rotate. PERIOD If the control system is not powered on you can not rotate the turbine into the wind. Do the math, you will need an extra wind turbine to generate power for these equipment loads for each three or four turbines. Or in different terms, if you have 10 turbines generating 20 Megawatts per hour (nameplate, total) then 2 megawatts are used 24/7/365/20 years. Weather they are making electricity or not. That is load added to the grid that has to be supplied. Without that power being leached from the grid the wind turbines do not work. PERIOD. And this article shows that after 10 years are so the turbins are doing nothing more than replenishing the power they leach from the grid.

Subsidies are based on net power produced. It’s almost like someone already thought of that and didn’t tell you.

The molten salt (or whatever they use) solar furnace collectors even have to waste money on the heating system for the molten salt. Then there are the thousands of motors and controllers for the mirror positioning equipment. Using data for a heavy duty antenna Azimuth/elevation position system you are talking several watts per mirror, which seems very conservative to me.

This report is dated 30 Dec 2012 and today is 29 Dec 2018 !

Could the reduced lifetime be due to bearing wear? Sure it would be calculated – for constant wear. But the swindlemills are not always turning at a constant rate.

This story reminds me of the classic mental exercise of asking “if a tree falls in the forest and nobody is there to hear it, does it make a sound?”

Without news coverage, the left has no worry about this study.