Guest post by David Middleton

THE 240MWE FACILITY IS THE LARGEST POST-COMBUSTION CARBON CAPTURE PROJECT IN THE WORLD

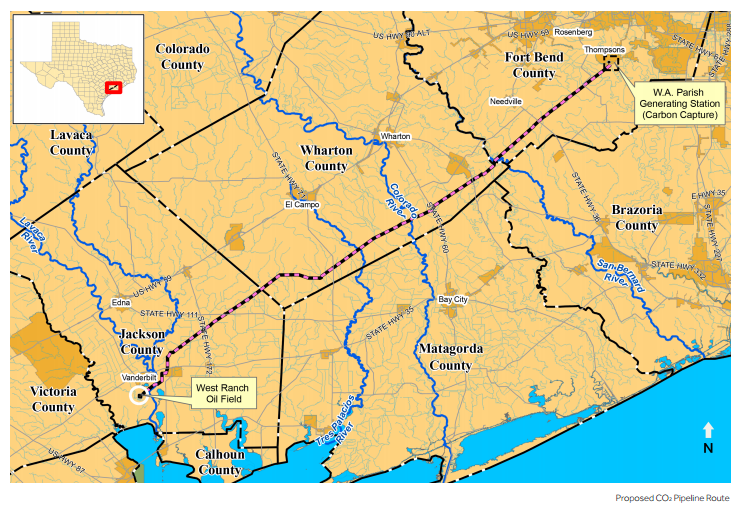

WASHINGTON, D.C. — Secretary of Energy Rick Perry took part in a ribbon-cutting ceremony today to mark the opening of Petra Nova, the world’s largest post-combustion carbon capture project, which was completed on-schedule and on-budget. The large-scale demonstration project, located at the W.A. Parish power plant in Thompsons, Texas, is a joint venture between NRG Energy (NRG) and JX Nippon Oil & Gas Exploration Corporation (JX).

“I commend all those who contributed to this major achievement,” said Secretary Perry. “While the Petra Nova project will certainly benefit Texas, it also demonstrates that clean coal technologies can have a meaningful and positive impact on the Nation’s energy security and economic growth.”

Funded in part by the U.S. Department of Energy (DOE) and originally conceived as a 60-megawatt electric (MWe) capture project, the project sponsors expanded the design to capture emissions from 240 MWe of generation at the Houston-area power plant, quadrupling the size of the capture project without additional federal investment. During performance testing, the system demonstrated a carbon capture rate of more than 90 percent.

At its current level of operation, Petra Nova will capture more than 5,000 tons of carbon dioxide (CO2) per day, which will be used for enhanced oil recovery (EOR) at the West Ranch Oil Field. The project is expected to boost production at West Ranch from 500 barrels per day to approximately 15,000 barrels per day. It is estimated that the field holds 60 million barrels of oil recoverable from EOR operations.

The successful commencement of Petra Nova operations also represents an important step in advancing the commercialization of technologies that capture CO2 from the flue gas of existing power plants. Its success could become the model for future coal-fired power generation facilities. The addition of CO2 capture capability to the existing fleet of power plants could support CO2 pipeline infrastructure development and drive domestic EOR opportunities.

The Petra Nova carbon capture system was installed in the W.A. Parish generation station. This is the largest and cleanest fossil fuel generaton station in the United States:

W.A. Parish Electric Generation Station, Thompson, Texas

Owner/operator: Texas Genco Holdings Inc.

Texas Genco has invested heavily in upgrading its W.A. Parish coal- and gas-fired plant southwest of Houston. Although this nine-unit, 3,653-MW plant is the largest fossil-fueled plant in America, its NOx emissions have been reduced to microscopic levels. Based on those levels, W.A. Parish could rightly claim that it is among the cleanest coal plants in the U.S.

Texas Genco’s W.A. Parish Electric Generation Station (WAP) is the largest coal- and gas-fired power facility in the U.S. based on total net generating capacity. It and its owner, Texas Genco Holdings Inc., operate in the Electric Reliability Council of Texas (ERCOT), one of the largest electric power markets in the nation. Over the past few years, the majority-owned subsidiary of Houston-based CenterPoint Energy Inc. has met the challenge of adding emissions control equipment to these baseload units while maintaining the availability and reliability required by ERCOT’s competitive market.

In the process, Texas Genco has emerged as an industry leader at reducing emissions and demonstrating new NOx-control technologies. The company’s fleet of plants operates at one of the lowest NOx emission rates in the country, and WAP likely emits less NOx on a lb/MMBtu basis than any coal-fired plant of any size in the U.S. Cleanliness is costly; the company has spent more than $700 million on new emission controls since 1999.

With the commissioning of another round of emissions-control equipment this year, NOx emissions from Texas Genco’s Houston-area power plants—including WAP—will be 88% lower than 1998 levels. These actions play a major role in the Houston/Galveston Area Ozone State Implementation Plan and are helping to clean the air in the greater Houston area. To honor the accomplishment, the W.A. Parish plant was recently given the Facility Award by the Power Industry Division of the Instrumentation, Systems, and Automation Society (Research Triangle Park, N.C.) for installing equipment to reduce emissions and improve reliability while minimizing operational costs.

[…]

The W.A. Parrish Generation Station has a generating capacity of about 3,660 MW (2,740 MW of coal and 1,190 MW of natural gas capacity). Its total capacity is approximately the same as the ten largest solar PV plants in the U.S. combined (3,713 MW). From 2002-2009, W.A. Parrish operated at 85% of capacity. The war on coal gradually reduced its operations to 57% of capacity in 2016.

The Petra Nova carbon capture system will enable the plant to capture about 90% of the CO2 from 240 MW of its coal capacity. It is expected to capture about 1.6 million tons of CO2 per year. The cost of the carbon capture system was approximately $1 billion, with the taxpayers picking up 19% of the tab. Normally, I would call this a pointless waste of money. It won’t have any effect on atmospheric CO2 or the weather. However, this carbon capture system actually serves a useful purpose:

The Captured CO2 will employ Enhanced Oil Recovery to enhance production at the West Ranch oil field, which is operated by Hilcorp Energy Company. It is expected that oil production will be boosted from around 300 barrels per day today to up to 15,000 barrels per day while also sequestering CO2 underground. This field is currently estimated to hold approximately 60 million barrels of oil recoverable from EOR operations

How Carbon Capture Works

The West Ranch oil field has produced about 390 million barrels of oil since 1938. CO2 injection will boost the production from 300 to as much as 15,000 barrels of oil per day. The EOR could lead to the recovery of 60 million barrels of oil that would otherwise be “left in the ground.” Irony is such a beautiful thing!

And the really cool thing about this project: It makes money!

FiscalNotes

NRG’s Petra Nova Plant Captures Carbon, Boosts Bottom Line

An interview with David Greeson, Vice President of Development, NRG Energy Inc.

by Brian Wellborn

NRG Energy Inc. (NRG) and JX Nippon Oil & Gas Exploration jointly operate the Petra Nova Carbon Capture project, the world’s largest retrofit post-combustion carbon capture system, at the W.A. Parish Generating Station southwest of Houston.

Fiscal Notes recently spoke with NRG Vice President of Development David Greeson to discuss the Petra Nova project and learn what makes its capture system unique, environmentally sound and profitable.

Fiscal Notes: What are Petra Nova’s broad environmental goals?

David Greeson: The goal of the Petra Nova project is to capture more than 90 percent of the carbon dioxide (CO2) in the exhaust flue gas from an existing coal-fired unit at the W.A. Parish power plant. We want to prove it’s feasible to build a carbon capture system on schedule and on budget. Demonstrating the system working at full commercial scale will provide a path forward to address CO2 emissions from existing coal-fired plants, both in the U.S. and around the world.

In addition, we’re looking to create a commercial structure that couples power generation with oil recovery for potential long-term viability — not only to pay for the carbon capture and storage system but also to provide an economic return for investors.

[…]

Fiscal Notes: How economically viable is Petra Nova’s carbon capture process?

Greeson: As long as oil is priced at around $50 per barrel or above, sales of the oil from the West Ranch field will pay for the Petra Nova project.

[…]

The price of CO2 for EOR projects is generally pegged to the price of oil. At >$50/bbl, the sale of the CO2 to Hilcorp will pay for the carbon capture system. Projects like this do not need subsidies.

This will enable the coal-fired plants to operate at a higher capacity and prevent 60 million barrels of oil from becoming “stranded assets.” I just love irony!

Addendum

4/19/2017

DOE estimates that CO2 EOR could recover about 85 billion barrels of oil from existing U.S. oil fields:

It actually does something. That’s the amazing part. That was by no means a requirement over the last eight years.

The crazy thing is that the $190 mm grant from the DOE was during the Obama maladministration.

Okay, we’ll call it an oversight then.

Even an incompetent blind squirrel occasionally finds a nut… 😉

for the last 8 years all it would have needed to do was run accross the White House lawn and wait for the Secret Service Prarie Doggies to pop their heads up out of the ground then play a great game of Whack-a-mole…Nuts abound

Well why not redesign all Natural Gas combustion systems to make them closed systems.

Combust the gas in a closed container, that is also a heat exchanger, then condense the water, and collect the CO2, and send it back through a pipe to the gas company to sell to oil drilling companies.

Should be able to supply all of the house water needs, from the gas combustion, so the water plumbing could be replaced by the CO2 recycle plumbing.

G

george e. smith: How many hours a day do you cook and heat your house, if you create enough water for bathing and drinking?

Go ahead and do that, after you install a chiller twice the size of your home air conditioner (and pay to burn enough coal to generate electricity for it). Or are you going to store all that hot gas in a tank the size of your house until it cools enough to remove the water?

Yes, the only large market for CO2 is to enhance oil recovery, so as you said, the irony is in full bloom for this project. Would like to know O&M costs. CO2 recovery is very energy-intensive and there are a lot of steps. Much of the equipment must be stainless steel. And by the way, much of the CO2 is “reproduced” during enhanced oil production…

Almost all of the CO2 will be “reproduced.” That’s how a CO2 flood works. “Cool” doesn’t even begin to describe this!

David,

Along the line of Greg’s question, do you know anything about the technology used to capture the CO2? Can you direct me to a site that discusses it?

https://sequestration.mit.edu/tools/projects/wa_parish.html

Thank you for the link, David!

David,

Fanning out from the link you kindly provided, I found what I basically was interested in: “In all these near-term technologies, an absorberstripper configuration is used as shown in Figure 2-1, with the solvent regenerated thermally using steam from the power plant. This steam extraction results in loss of power production at the host plant, and when combined with power needed for compression, results in a parasitic load of 20-30% for CO2 capture and compression, with net plant efficiency dropping from 38% to 27%.”

You and readers might be interested in the full article: http://www.globalccsinstitute.com/sites/www.globalccsinstitute.com/files/publications/29721/co2-capture-technologies-pcc.pdf

The plant has 2,470 MW of ccoal-fired capacity. The CCS will only affect 240 MW, about 10% of the capacity.

David,

The thing about sequestration is that, as NASA has discovered, there is no such thing as a free launch. There are costs involved that most directly translate into lowered efficiency and therefore higher costs to the consumer. In this particular case, the costs are offset by being able to sell the CO2 and have it go to some good use. I’m concerned about the future as greenies demand that all CO2 be sequestered and just buried in the ground, without concern for the decreased efficiency.

I share your concern.

GREG in Houston: “the only large market for CO2 is to enhance oil recovery”

What about carbonated beverages? Some beverages create their own natural carbonation, while others require direct injection of CO2. That CO2 is intended for human consumption.

Thankfully, “much of the CO2 is ‘reproduced’ during enhanced oil production” – because why would anyone strive to sequester underground the base of the food chain for all carbon based life forms?

I believe that most of the CO2 for beverages is produced on site from chemical reactions.

I believe the same goes for the CO2 cylinders that are distributed to restaurants and fast food places.

I’m thinking that I wouldn’t want my beverages carbonated with flue gas from a power plant.

There are severe restrictions on industrial effluent. You’d never get the FDA to approve using it in food products.

Whew, I was worried there for a minute.

I was merely trying to point out that there are existing ‘large markets for CO2’, not necessarily that the scrubbed CO2 could be used for that purpose.

But several of you have raised interesting points and now I’ve got other questions, like when ‘Ben of Houston’ says: “You’d never get the FDA to approve using it [scrubbed CO2] in food products” – is this because the scrubbed CO2 might be contaminated and the FDA would not approve any contaminants for consumption? They can’t knowingly allow for pollutants to be used as consumable ingredients, right?

How then do they allow Carbon Dioxide itself to be added to consumables if it is a pollutant? (Answer: CO2 is not a pollutant.)

Thomas you are mistaking pollutant for poison.

The FDA don’t care about pollutants, they care about poisons.

I have used dry ice, produced from a well, and then purified, so some CO2 that is produced from the ground, is used in beverage production. The well is in an area which has natural gas wells as well.

http://minerals.statedevelopment.sa.gov.au/__data/assets/pdf_file/0014/254120/caroline_eir.pdf

I have heard of capturing carbon dioxide from breweries for beverage use.

Thomas Homer you might be interested in this article:

http://ethanolproducer.com/articles/9654/air-liquide-to-capture-carbon-dioxide-from-calif-ethanol-plant

“The new 450-ton facility, located in Tulare County, will capture carbon dioxide gases from an ethanol plant owned by Calgren Renewable Fuels LLC. The carbon dioxide recovered will then be purified and liquefied by Air Liquide to meet beverage grade specifications for the diverse food, beverage and manufacturing industries in the region.”

Why does injected CO2 work any better than if you just injected air down there? Or, is it just because the CO2 then is sequestered beneath the surface that is the big deal?

Start on page 4…

https://www.netl.doe.gov/file%20library/research/oil-gas/CO2_EOR_Primer.pdf

“How then do they allow Carbon Dioxide itself to be added to consumables if it is a pollutant?” Have you heard of thermal pollution? “Thermal pollution is the degradation of water quality by any process that changes ambient water temperature. A common cause of thermal pollution is the use of water as a coolant by power plants and industrial manufacturers.”

Manure is added to fields, but in the water supply manure is a pollutant. Nitrates are added to food, yet in rivers nitrates are pollutants.

Something is a pollutant not because of its inherent properties but because it is in the wrong place.

There may be arguments for CO2 not being a pollutant, but allowing it it be added to consumables is certainly not one of them.

seaice1

I would slightly amend that definition of pollution: “A substance … in the wrong place at the wrong concentration.”

Even table salt can pollute: Too little on the food, too much on the food, any (visible salt) spilled on the table, any (amount of salt) at all dropped into a distilled water sample. But tons of salt “spilled”” on the road can be needed, or can break up the concrete in the wrong place.

Air has oxygen in it. Oxygen and flammable liquids do not mix well.

seaice1 says: ” Nitrates are added to food, yet in rivers nitrates are pollutants.”

Not sure this is your best example to add to your argument, just read this on the internet …

[ Manufacturers add nitrates and nitrites to foods such as cured sandwich meats, bacon, salami or sausages to give them color and to prolong their shelf life. When added to processed foods in this way, both nitrates and nitrites can form nitrosamines in the body, which can increase your risk of developing cancer. ]

Carbon based life forms need carbon, and all of the carbon in all carbon based life forms comes from Carbon Dioxide.

We haven’t even broached another large market for CO2 and that’s for actual greenhouses to increase productivity. Many benefits of increased CO2, any detriments?

Mid-low $40s/ton of CO2 full cost. O&M plus capital recovery.

Market CO2 from natural geologic domes is more like $15-20/ton.

The only reason the economics work here is because there is no other economic CO2 supply in the area. Many areas that have oil that can be recovered through EOR also have access to natural CO2 domes. If oil prices go up, there will be insufficient natural CO2 supply. Today, there is plenty.

That’s Denbury’s business model.

http://www.denbury.com/operations/rocky-mountain-region/co2-sources-and-pipelines/default.aspx

This project is all about recovering the otherwise untouchable oil from the West Ranch field. To make it profitable, they needed much more CO2 than could be gotten from the original 60 MW project, that is why they upsized it to 240 MW. Also, note that the steam to stripper comes from a separate, gas-fired combined cycle unit that also generates its own electricity, at high efficiency.

One more fun fact about the project, they use a proprietary solvent that needs less steam to regenerate than the traditional one, MEA. Its parasitic load is under 25%, when the older MEA solvent needs around 35%. An improvement.

Exactly. Cenovis started doing this in Weyburn Saskatchewan a few years ago. Leading edge at the time. Boundary Dam coal plant was said to use up to 40% of generated power to capture carbon dioxide or something like that. Of course the CO2 used to push the oil out of the fissures comes up with the oil and becomes un-captured. It will also mix with H2S gas to create acid which rots all but the highest quality stainless steel. Also pushes the emulsion to the surface and eliminates the need for the pump-jack in the drawing.

Carbon capture was added to one unit (200mw)at Boundary dam plant in Saskatchewan. As I understand it, the federal government wouldn’t grant an approval for the rebuilt plant without the CCS “upgrade”, which cost a billion and hasn’t worked right while using about 80mw just to run the CCS. This is just more cost on ratepayers from useless CO2 regulation.

You’re missing the truly big picture though. Since this project was intended to make money, it did something no other government sponsored project ever does. Finish on time and on budget.

And at 4 times the capacity of the original plan. The DOE grant was for a 60 MW CCS demonstration project. They delivered a 240 MW CCS that will make money right off the bat.

Cool, one of my son in laws was a part of this project. The Houston/Omaha/Japan flights were a killer though. On time and on budget. Were government ‘people’ forbidden from making helpful suggestions?

Who intellectually masturbated this unnecessary boondoggle?? And to do what—give be a brake.

If it makes money, and the captured CO2 is put to good use, why would you call it a boondoggle? And why do bees need brakes?

I bet his auto-correct wanked on him. 😉

Maybe he has a cold 🙂

In addition to EOR, other CO2 supply uses include extraction of pharmaceuticals, carbonation of beverages and greenhouse addition. Most of the CO2 is recovered from refinery, chemical, alcoholic beverage and fertilizer manufacturing.

CO2 is used to decaffeinate coffee, cocoa and tea leaves…

https://en.wikipedia.org/wiki/Decaffeination#CO2_process

The Sabatier reaction or Sabatier process was discovered by the French chemist Paul Sabatier in the 1910s. It involves the reaction of hydrogen with carbon dioxide at elevated temperatures (optimally 300–400 °C) and pressures in the presence of a nickel catalyst to produce methane and water. Optionally, ruthenium on alumina (aluminium oxide) makes a more efficient catalyst. It is described by the following exothermic reaction:

CO2 + 4H2 → CH4 + 2H2O + energy

∆H = −165.0 kJ/mol

CO2 is a valuable gas.

The main issue for atmospheric CO2 is leaf production.

Many experiments have suggested that leaf tissues of living plants emit methane. Eg.

Title: Methane emissions from terrestrial plants under aerobic conditions

Authors: Keppler, Frank; Hamilton, John T. G.; Braß, Marc; Röckmann, Thomas

Affiliation: AA(Max-Planck-Institut für Kernphysik, Saupfercheckweg 1, 69117 Heidelberg, Germany), AB(Department of Agriculture and Rural Development for Northern Ireland, Agriculture, Food and Environmental Science Division, Newforge Lane, Belfast BT9 5PX, UK), AC(Max-Planck-Institut für Kernphysik, Saupfercheckweg 1, 69117 Heidelberg, Germany), AD(Max-Planck-Institut für Kernphysik, Saupfercheckweg 1, 69117 Heidelberg, Germany)

Publication: Nature, Volume 439, Issue 7073, pp. 187-191 (2006). (Nature Homepage)

Publication Date: 01/2006

Origin: NATURE

DOI: 10.1038/nature04420

Bibliographic Code: 2006Natur.439..187K

Abstract

Methane is an important greenhouse gas and its atmospheric concentration has almost tripled since pre-industrial times. It plays a central role in atmospheric oxidation chemistry and affects stratospheric ozone and water vapour levels. Most of the methane from natural sources in Earth’s atmosphere is thought to originate from biological processes in anoxic environments. Here we demonstrate using stable carbon isotopes that methane is readily formed in situ in terrestrial plants under oxic conditions by a hitherto unrecognized process. Significant methane emissions from both intact plants and detached leaves were observed during incubation experiments in the laboratory and in the field. If our measurements are typical for short-lived biomass and scaled on a global basis, we estimate a methane source strength of 62-236Tgyr-1 for living plants and 1-7Tgyr-1 for plant litter (1Tg = 1012g). We suggest that this newly identified source may have important implications for the global methane budget and may call for a reconsideration of the role of natural methane sources in past climate change.

http://adsabs.harvard.edu/abs/2006Natur.439..187K

Effects of elevated pressure on rate of photosynthesis during plant growth.

Takeishi H1, Hayashi J, Okazawa A, Harada K, Hirata K, Kobayashi A, Akamatsu F.

Author information

Abstract

The aim of this study is to investigate the effects of an artificially controlled environment, particularly elevated total pressure, on net photosynthesis and respiration during plant growth. Pressure directly affects not only cells and organelles in leaves but also the diffusion coefficients and degrees of solubility of CO2 and O2. In this study, the effects of elevated total pressure on the rates of net photosynthesis and respiration of a model plant, Arabidopsis thaliana, were investigated in a chamber that newly developed in this study to control the total pressure. The results clearly showed that the rate of respiration decreased linearly with increasing total pressure at a high humidity. The rate of respiration decreased linearly with increasing total pressure up to 0.2 MPa (2 ATM), and increased with increasing total pressure from 0.3 to 0.5 MPa at a low humidity. The rate of net photosynthesis decreased linearly with increasing total pressure under a constant partial pressure of CO2 at 40 Pa. On the other hand, the rate of net photosynthesis was clearly increased by up to 1.6-fold with increasing total pressure and partial pressure of CO2.

https://www.ncbi.nlm.nih.gov/pubmed/23994480

In summary, more CO2, more leaves. More leaves, more atmospheric methane. Is it a problem? No-one knows and few are investigating it.

The reverse process is widely used which is called steam reforming of Methane to manufacture Hydrogen. CO2 is the byproduct of that process. Hydrogen is much more valuable and widely used in many Refining upgradiing processes. Most Oil Refineries have Hydrogen plants inside the gate. Never heard of anyone commercially using Hydrogen to make Methane.

But isn’t this ‘captured’ CO2 ultimately released into the atmosphere after being sold?

Can’t stop the world from melting like that.

The only reason this facility can claim it is cost neutral is that the whole operation is based on CO2 economics in which a local market is available. Remember that they are recovering 90% of less than 10% of the plant capacity for CO2, hardly a breakthrough in emissions reduction. If the plant were expanded to capture more, the CO2 price would drop and it would be impossible to justify the process on economics. No demonstration plants are needed to prove the indisputable fact that CO2 capture from a conventional coal-fired plant adds 30% to the cost to produce the electricity, and there is not a large enough market for CO2 to compensate for those costs. I also suspect that some of the very cheap fuel gas that is already piped to the station is used to fire the regenerator, another local factor that helps the economics.

As a resident within the range of this plant I am ok with the project as long as they do not try to tease more CO2 capture than the market will allow. But I also suspect that their accountants are as creative as the engineers that devised this system, and those that want to promote this technology will continue to press for it using suspect accounting methods and false promises of intangible benefits.

They actually expanded the carbon capture to 240 MW from the planned 60 MW capacity. This was driven by the need for CO2 for the EOR at West Ranch oil field. And they were very creative in financing the project. Rather than selling the CO2 to Hilcorp, they took a working interest in the field…

http://www.paulsoninstitute.org/wp-content/uploads/2015/10/CS-Petra-Nova-EN.pdf

profit or “works” at $50 a barrel hmm?

well oils at 40 ish n likely to stay there.

frakking profits need it at 80 or so a barrel

and

I am waiting for the quakes to start in not too long a time frame as is happening with just extraction in nearby states nearly daily shallow 2 to 3+level shakes

and like all the rest of the co2 “burials”

somewhere a weak spot will spring a leak

http://oilprice.com/commodity-price-charts?1=&page=chart&sym=CL%2A1&domain=advancedmedia&sg=true&display_ice=1&enabled_ice_exchanges=&studies=Volume%3B&cancelstudy=&a=W

The West Ranch oil field has been producing since 1938. It has produced 390 million barrels. The CO2 EOR will recover another 60 million barrels.

The cost of the project is about $1 billion. This works out to $16.67/bbl.

zspeaksup: If you can explain to me how a simple donkey engine can create earthquakes hundreds of miles away, I would love to hear it. Because that is how far most of these “caused” earthquakes are from the areas being fracced.

Regardless, you have absolutely no knowledge of the difference in power involved here.

Finally, if fraccing does “cause” an earthquake, it was an earthquake that was already poised to happen. The energy was already in place, it just needed a tiny bit more energy to trigger. If the fraccing hadn’t triggered it, the gradual build up of stress in the crust would have in the next few months.

The technology of Carbon Capture Utilization is another method of removing the CO2 out of combusted fossil fuel exhaust, but with this technology the CO2 is transformed into useful saleable products. No pipelines are required, and it can’t “leak” back into the atmosphere. Full time jobs in a number of sectors will be created, and this process requires no steam from the power plant and only a minimal amount of electricity. The CO2 transformation happens in an atmospheric reactor and this CCU System costs a fraction of what a CCS System costs.

There are alternatives to Carbon Capture Sequestration.

The Petra Nova Fact Sheet has a typo, I think..”It is expected that oil production will be boosted from around 300 barrels per day today to up to 15,000 barrels per day”….That should be “from 500″…

Great post though.

And so does David…”will boost the production from 300 to as much as 15,000 barrels of oil per day. “

There’s no typo.

The DOE press release says 500 bbl/d. All of the NGR documents say 300 bbl/d.

When I see the government and a business saying two different things, I go with the business.

Whether the field is currently limping along at 300 or 500 bbl/d, the EOR could boost production to 15,000 bbl/d.

Diagram # 3 above and below shows 500 and shows 30 X 500 = 15,000…or I need new glasses ? LOL

The diagram does say 500. All of the other NRG documents say 300. Does it matter? The key point is that the EOR could boost production to 15,000 bbl/d.

Well, at least I don’t need new glasses… :o)

PS: I know the little cartoon shows the CO2 being sequestered, but that’s not entirely accurate.

Which part is “not entirely accurate”?

http://www.nrg.com/images/business/carbon-capture-phase-3.png

Hilcorp is buying the CO2 to inject it in the oil reservoir. It doesn’t make much sense to vent the CO2 rather than re-inject it.

What happens after production is finished on the fields? Are the wells capped and the pressurized CO2 left underground?

Seems to me it would be safer when mothballing the field, to let the CO2 bleed off and cap the now depressurized wells.

I was thinking that if there was a sudden catastrophic failure of the cap, all that pressurized CO2 could come out in a short period of time, cooling as it depressurizes. Resulting in a ground hugging cloud of almost pure CO2 drifting downwind.

The main reason that this produces more oil is that the injection keeps the reservoir pressure as high as it was before oil production. So the zone won’t be “pressured up” after it’s abandoned.

The CO2 fills the void space that was originally filled with oil and natural gas. The reservoir pressure will be lower at the end or the field’s productive life than it was when it was first drilled, despite the injection of CO2.

When the wells are plugged and abandoned, there is no possibility of a “catastrophic failure.” Some CO2 may eventually leak to the surface.

CO2 is heavier than air…

there is no possibility of a “catastrophic failure.”

================

and the Titanic was unsinkable, so why worry about lifeboats?

David Middleton, I am not certain CO2 is recovered from the produced oil/gas stream. In any case, no recompression of the CO2 is shown. The relatively small amount of CO2 would probably not be economical to recover. The cartoon at the very bottom of the article shows no CO2 recovery.

Prior to the Titanic, the purpose of life boats was to ferry passengers from the vessel in trouble to a rescue vessel.

http://www.nrg.com/images/business/carbon-capture-phase-3.png

The tank to the right of the pumper jack is labeled “CO2-Oil Separator.” The oil goes into the “black” pipeline. The CO2 goes into the “green” pipeline and runs back to the “pink” valve junction to the left of the pumper jack where it is mixed with the CO2 from the power plant and re-injected.

It’s a schematic diagram. There has to be a compressor at the site of injection. Re-injecting the produced CO2 is just a matter of plumbing.

David, compression of this produced CO2 is much more than a matter of plumbing. I’m sure you know CO2 in this use is a high pressure semi “liquid,” so the CO2 off the separator would have to be repurified, dehydrated and pressurized from atmospheric pressure to well over 1000 psig. Also, the CO2 stream would be relatively small. This is much more than just plumbing – this is another mini-CO2 plant.

You’re putting it back into the reservoir it just came out of.

All you have to do is to separate the liquids from the gas in the separator tank, compress it and pump it back down one of the injection wells.

What about the transport piping between the power plant and the well? I assume it is pressurized, is there a risk of it leaking and causing a CO2 disaster?

And some of the CO2 does indeed stay in the ground, dissolved in the heaviest oil and longer chain hydrocarbons that cannot flow to the well. A former DOE official has been advocating this for years, saying that increased use of CO2 for EOR would sequester (leave in the ground) more CO2 than requiring all new coal plants to inject all of it underground and leave it.

I wonder how this thread will do as far as drawing trolls. One thing the story does not mention is what the price of the power generated is, especially relative to “renewables”.

Texas wholesale electricity prices range from $20-30/MWh.

re: “Texas wholesale electricity prices range from $20-30/MWh.”

WHICH the “retailers” turn around and charges Texas residential customers from $70 to $115/MWh *plus* delivery charges (and other incidental fees) adding $40 to $70/MWh to that.

Power co-ops (user owned cooperatives) and profit-makers (like TXU) are at the low and high ends of those ranges respectively.

The retailers have to make money as do companies like Oncor that manage the transmission system.

Have you seen the difference between wholesale and retail in grocery stores? For most products the markup is at least 50%. Yet the profit margin for grocery stores in general is on 2 to 3%.

The reason for this is that the retailer has costs. Lots of them. These costs have to be covered.

Yep.

Since the CO2 recovery business pays for itself @$50/bbl, the answer can be indicated by retail electrical fees. In Houston, those rates range for the homeowner from 8.9 to 10.9 cents/KWH, which is provided via a mix of production methods.

Here in lovely California it’s 2 to 3 time that. At my business, I pay about $.25 KWH.

I imagine that the extra oil being produced by the field, once burnt, will put more CO2 into the atmosphere than the carbon capture equipment took out.

Wouldn’t that be ironic.

I LOVE irony! Don’t forget the carbon footprint of an extra 60 million barrels of oil!

David, a few years back I was representing the company I was working for in the European CO2 sequestration project. The problem they had was energy balance. Conventional Flue gas contains 78% nitrogen. The energy required to inject this large volume of CO2 +N2 into the deep sequestration beds was consuming a large percentage of the electricity generated from the power plant. But if you were able to filter the Nitrogen out of the intake combustion air, so you were burning the coal with +90% O2, you could reduce the effluent volume by 75% or more. This of course greatly decreased the energy required inject the flue gas into the sequestration beds.

In this case the Oil company is footing the bill for injecting the CO2 into the ground, but the energy balance is the same.

Yes, Tom, that is called an oxyfuel process. The major drawback is the energy required to separate the oxygen from the air, currently about a 25% energy penalty.

Sorry for the repeated adds, but…. I doubt much of the CO2 is recaptured at the wellhead and re-injected. That would be hugely expensive.

Diagram # 3 above shows that it is recaptured and reused….

Yes it does. The gas has to be separated from the oil before putting the oil into the pipeline. Hilcorp can either re-inject it or vent it. Since they’re buying CO2 from NRG, it would make sense to re-inject it.

That capture and re-injection has been used for over 50 years…..

I think SACROC was the first CO2 EOR in 1972.

Greg, Why don’t they just use atmospheric air? Is there some reason it has to be CO2? Good thing the CO2 is not sequestered, otherwise we might run out of O2!

To answer my own question, Wikipedia says CO2 is preferred because it reduces the surface tension of oil and it’s cheaper than other alternatives.

I would think that you would want to remove the O2 before injecting air from the atmosphere.

Oil and O2, not a good combination.

could be they are pressuring/heating the CO2 until it is super-critical, at which point it functions as a solvent.

I don’t know how much good heating the CO2 would do, since it still has to be piped down to where the oil is. Lots of rock to lose that heat to.

There are many facilities out there that inject CO2 in to wells for EOR. H2S, also. Pressures in the facilities tend to be very high >3000psi. They have to be high in order to inject the well. Working in the facilities tends to be potentially dangerous. For the facilities I have been to, I, and those working with me, have been required to be “under air”. Under air means you are required to wear an air supplied respirator whenever you are on the unit.

Oxygen combusts hydrocarbons, especially at high pressure, which would basically cause an underground fire or worse and generate CO2. N2 has no solvating properties for hydrocarbons like CO2 does.

CO2 can be liquefied at moderate pressures so can be stored and pumped as a liquid with densities close to 1kg/L. Like all liquids, it acts as a solvent and is pretty much totally miscible with hydrocarbons. Dissolving CO2 into oil will reduce its viscosity. Gas requires huge pressures to get anywhere close to these densities. Liquids are incompressible, so do not store much energy at increased pressure. (A gas requires a reduction of about 1/2 volume to double the pressure. A liquid will double the pressure with a tiny reduction in volume.)

CO2 is supercritical above 31C and 73 bar pressure, but the critical density is only 0.46Kg/L. Supercritical fluids are compressible, so again you require lots of energy to increase the density.

Not sure what conditions the oil is under. If it is over 31C, 73 bar then we will have a supercritical fluid, if below will have a liquid.

Injecting oxygen/air is called fireflooding. Lots of issues were found by oil companies that actually tried it in the 60s-70s.

CO2 is a solvent for oil, it’s like washing grease off your tools with paint thinner. There are even techniques for using liquid CO2 as a dry cleaning solvent. Then when use reduce pressure the CO2 just boils off and you can re-compress it or vent it.

It’s not expensive at all if you are separating gases from liquids and aren’t caring about residue of the gas in the liquid (or vice versa). You can do that in a simple holding tank and a compressor pushing the gas into the recycle.

The pressurization is not done at the well head, but some distance away. Part of the purpose is to push oil TOWARD the well, not AWAY from it. As a result, it should actually take a considerable amount of time for any of the injected CO2 to reach the wellhead. When it does, it will still be at a lower concentration than at the injection point.

There may well be merit in the system if it is able to generate electricity, revenue and enhanced oil recovery at a profit. I would agree the least valuable part of this is the reduction in CO2 emissions to the atmosphere. The benefits of that are all anchored in climate models and exaggeration of what scientific evidence there is of CO2 impact on tropospheric temperature and weather events. Consider the potential idiocy of this application in a cooler climate where the fossil fuel generation may be used to a considerable extent in cooler months to generate heat in home and businesses while the CO2 emissions are captured in order to “prevent heat in the atmosphere”.

Carbon Capture is a waste of time and money because: 1. Plants are CO2 deficient and need about 1500 ppm to optimize growth. 2. CO2 is not an air pollutant Because it doesn’t kill Humans until CO2 levels reach 60,000 ppm. 3. Atmospheric CO2 has an insignificant effect on Atmospheric temperature. 4. 100 million Gigatons of CO2 have been sequestered in the Earth by Natural Processes.

60 million barrels of oil is worth $3 billion at $50/bbl. Spending $1 billion to make $3 billion is not a waste of money.

Unless by extension and in the wrong policy hands it leads to $30 billion is wasted projects justified by the one good one or hidden with averages like Obama did.

David, it’s a waste of money one could just go find other oil that can be recovered cheaper. Still it’s a cool article and I learned something. So thanks!

No. One can’t “just go find other oil that can be recovered cheaper.”

$1 billion for 60 million barrels works out to $16.67/bbl. The average F&D cost in the Permian Basin is $23.80/bbl, the Bakken is $22.96/bbl.

No one would walk away from a $16.67/bbl F&D.

Are you declaring that the people who have spent their entire lives drilling for oil don’t know how to do a simple cost benefit analysis?

Spending $1 billion to make $3 billion is not a waste of money.

============

unless of course the market price of CO2 from other sources is lower.

There are no other sources of CO2 for this field. They built the CCS at the W.A. Parrish power plant and the pipeline from the power plant to the West Ranch oil field for the purpose of injecting the CO2.

There’s the raw cost of the CO2, plus the cost of shipping it to the site.

The coal power plant in question is pretty close.

David, You obviously know more about oil production than I do. It makes sense though. The well is already drilled and outfitted, might as well get the oil out if it’s not too expensive. And according to your numbers it’s definitely not.

Number 1 might be possible, then again, that might be too much for some plants. Granted CO2 is not a pollutant at normal to enhanced levels, however, using humans as your litmus is probably poor since that particular race seems to be pretty hardy – it may be deadly at much lower levels for most of the things we eat, for instance. I accept #3 at face value, and #4 only goes to show that we aren’t being Robinson Crusoe if we do stick some in the ground – Mother nature did it first, and she is pretty good at teaching us when we pay attention.

Perhaps so, but only 19% of what is wasted is public money. This is a rarity. If the article is correct, the project is self-funding at $50/bbl oil price and nothing is wasted. Even if oil drops below that price, another effect of the project is to boost the generation output of the coal portion of W. A. Parrish station from its recent values, which will benefit the electric utility customers. This seems to be very different than the usual Green energy pipe dream.

Typo, make that “waste of money *if* on could just …”

This thing just sounds like a scaled up version of an amine scrubber.

The diagram says they use a solvent. I’d be interested to see some more technical details.

Me too. CO2 dissolves in amine, so i guess you could consider it a solvent. Once you heat the amine it gives off the CO2… If that is what it is, then this technology has been around for decades although, maybe not at this scale.

It is a sterically hindered amine – similar to MEA but lower volatility (lower losses) and better loading and stripping characteristics. Basically, CO2 adds on at low temperature and comes off at high temperature, so you simply heat and cool the amine to load or strip the CO2.

The solvent is actually a mixture of monomethanolamine and dimethanolamine and some magic fou-fou dust the manufacturer, Mitsubishi, refuses to divulge.

Yes, and the solubility of amine solvents for CO2 is high because of acid-base interactions.

Why in the world are we capturing carbon when it is now more than obvious that plants want more CO2 in the air where it belongs? http://www.nature.com/nature/journal/v488/n7409/full/nature11299.html

TOMM,

If “plants want more CO2” then let them bid on the CO2. We wouldn’t want them to be freeloaders! They need to pay their way in the world.

Clyde, they do that by sacrificing their children for my consumption.

It is also ironic that Saskatchewan has already built a CO2 sequestration plant at the Boundary Dam coal fired power plant, (Unit #3 – 160 MW) sequestering about 1.2 billion tons of CO2 per year for sale to Cenovus at $25 Cdn a tonne which is also used to extract more oil by injection by the same process as identified in the article. The irony is that Canada is implementing a graduated carbon tax, which Saskatchewan wants no part of, but gets no bonus points for pioneering one of the first large scale carbon sequestration plants in the world. Saskatchewan puts its money where its mouth is and on the line to implement this, and then gets no respect from the federal gov’t for actually doing something that everyone says must be done.

David, what is your analysis of using surplus renewable electricity to split CO2 into CO (carbon monoxide) and use CO as a power source fuel or feedstock for further refining? I know it consumes more energy than gives back, but is it a plausible method in the future to create a new source of renewable hydrocarbons? Could this be the mythical “storage battery” that everybody talks about needing to some day scale back fossil fuels probably from depletion and price point? If viable, we could eternally keep our carbon based fuel infrastructure, the only difference being that this renewable carbon fuel/products would be sourced from CO2 and perhaps renewable energy that currently doesn’t work so well in our present grid.

Canadian utilities are not allowed to build any new coal generation without CCS. So, to learn how to the new technology works and get 100+ MW of compliant power, they rebuilt the unit and added the CCS.

Am I missing something here or does the economics of this seem more like a lemonade stand where the sale of lemonade seems to be making money…as long as you don’t include the sunk capitol expenditures? I recall reading that the taxpayers footed about 20% of the construction. How will the taxpayers get paid back from this money making venture?

The taxpayers never get paid back.

There would definitely be a payback to the economy. However, the royalties will go the the mineral owners, not the government.

The government will get some tax revenue from the enhanced economic activity.

The only minerals that belong to the Federal government are those under Federal lands and waters.

In most cases, the mineral rights came with the surface deed. However, over the years mineral rights have been sold, severing the surface and mineral rights.

When the surface owner doesn’t own the minerals, they aren’t always cooperative with efforts to exploit those minerals.

@Forrest Gardener “So in the US the minerals don’t belong to the government?”

It’s really complicated in the US, but most land is bought and sold without the mineral rights. The laws regarding mineral rights are based on English Common Law, East of the Mississippi, French Common law in Lousianna purchase states and finally Spanish Common Law in Texas and the land annexed due to the Mexican-America War. The majority of land from the Eastern Rocky Mountain foot hills to the west coast is owned by the federal Government.

Any serious questions about mineral rights in the US needs a lawyer that specializes in that field.

will this increase the fizz in my soda?

Nope.

Lets see how reliability goes. Mitsubishi uses the amine process. So does Boundary Dam in Saskachewan, although not a Mitsubishi design. Severe reliability problems. Amine works well to scrub CO2 from natural gas in its reducing environment. Boundary Dam problems arise from the ‘dirty’ oxidizing environment of flue gas.

Issues with fly ash?

Limited info, since Boundary Dam is a CCS ‘failure’. Biggest issue appears to be oxidation reactions cruding up the amine and necessitating multiweek shutsowns for cleaning stuff.

Wonder if it is an issue with their FGD… Maybe getting some sulphuric acid carryover…

This is horrible news. We need more CO2 in the atmosphere, not less. I want the plant life on the planet to thrive with abundant CO2.

Why is finding a way to get more oil out of the ground so terrible? When that oil is burned it will create more CO2 that was used to recover it in the first place.

Perhaps I misunderstood. I am full of flu meds today. But I understood some CO2 was to be sequestered. I am all for burning oil. The more the better.

The CO2 is being sequestered in order to force more oil to the surface.

“Projects like this do not need subsidies.” So the current payments by government have to stop and the government needs to be paid back the money that has already been spent on this project. The sequestered CO2 will someday reenter the atmosphere. There is no real evidence that CO2 has any effect on climate and plenty of scientific rational to support the idea that the climate sensivity of CO2 is zero. So projects like this will have no effect on climate.

The government already gave them the money years ago. There are no “current payments.” Since DOE grants don’t normally include claw-back provisions for projects that come in under budget, ahead of schedule and with four times the initially expected capacity, I don’t think the government will get paid back directly.

It CO2 is a pollutant, as per the EPA endangerment finding, they why does it have a market price greater than 0? If something is a pollutant, shouldn’t the price be negative? Shouldn’t people be charging you money to take it off your hands?

Because Hilcorp wants to recover 60 million barrels of oil.

Because CO2 in the air is of no use to anyone. Even CO2 at 20% in flue gas is not much use (may be to greenhouse owners?) Purified then pressurised in cylinders or liquified in pipelines and people have all sorts of uses for it. Enhancing oil recovery is one of them.

People will pay you money to take it off your hands if you can get it up to near purity. However, the market is limited, and supply and demand suggests that if all CO2 emissions were purified there would be very little value in the product.

“Because CO2 in the air is of no use to anyone.”

Unless you are a plant, someone who eats plants, or someone who eats things that eat plants.

Perhaps it would be more accurate to say it has no commercial value at atmospheric concentrations.

It is not inconsistent to discourage the emission of something into the atmosphere for which there is a market value. Methyl isocyanate would be a good example.

David already answered that question the first time it was asked.

The CO2 fills the void space that was originally filled with oil and natural gas. The reservoir pressure will be lower at the end or the field’s productive life than it was when it was first drilled, despite the injection of CO2.

When the wells are plugged and abandoned, there is no possibility of a “catastrophic failure.” Some CO2 may eventually leak to the surface over time.

Injecting CO2 is basically just the reverse of extracting the natural gas.

The fate of the void space depends on the reservoir drive mechanism. If it’s a water-drive reservoir, the void space is filled with brine, with little pressure depletion. If the reservoir is a pressure-depletion drive, the void space is filled with oil, with a very significant pressure depletion. The pressure depletion can actually “crush” the reservoir, particularly if the matrix isn’t “grain on grain.”

CO2 injection is most efficient in pressure-depletion reservoirs. Water injection is most efficient in water drive reservoirs.

Although, CO2 injection can work to flush more oil out of water drive reservoirs and water injection can work in depletion drive reservoirs.

The clay mineralogy can dictate what can and can’t be pumped into the reservoir. You don’t want to pump something into the reservoir that will turn the clay into cement.

Big time.

http://www.denbury.com/operations/operations-overview/default.aspx

I’m confused..Why would they refill it with oil ?

It wouldn’t “refill.” This is the oil that was left behind due to pressure depletion.

Pressure-depletion oil reservoirs generally have very low recovery factors (10-20%).

Got it, thanks

Wouldn’t compressed air be cheaper?

http://neori.org/resources-on-co2-eor/how-co2-eor-works/

I really don’t believe you want to be pumping a chamber full of oil, with O2.

On the other hand, one small spark would give a whole new meaning to fraccing.

I wonder how much energy is used to drive this process and by how much does it reduce overall efficiency?

Somewhere around 25-30% reduction in efficiency.

It seems to me that it would be MUCH cheaper and more efficient if waste paper, cardboard, bark, scrap wood etc. were simply buried in a landfill. This would eliminate the added cost of the separate process paths for garbage and “Recyclables.” That carbon which nature has captured for free, once buried, will stay there for hundreds of years. The trees will continue to capture the carbon which can then be processed into usable products and buried in the ground after used with a much lower cost than required to capture the same amount of carbon from the emissions of a combustion process.

When the plants hear of this they will be very upset. They will want to know why we are trying to deprive them of food.

When the oil recovered by this process is burned, it will produce more CO2 than what was used in the recovery process. So the plants will be thankful, not deprived.

Don’t leave out the nuts and flakes… That would be insensitive. 🙂

If you are going to be injecting CO2 into the earth anyway, you may as well do something useful with it, such as supercritical fluid extraction of petroleum residues from fields no longer able to produce primary or secondary product. Besides, someday, sooner or later, we’ll be able to get all that CO2 back when we need it for enhanced high-intensity food production. 🙂

CO2 sequestration is a misguided follow-on to the technologically misleading concept of ‘carbon footprint’. The planet atmosphere came dangerously close to the low level which would have resulted in extinction of all land plants and animals at the end of the last glaciation. It is still impoverished for CO2. Following are CO2 levels at various times and conditions:

Carbon dioxide levels, ppmv

40,000 Exhaled breath

20,000 No symptoms in healthy young people below this level

8,000 OSHA limit for 8 hr exposure

5,000 OSHA limit for continuous exposure

5,000 Approximate level 500 million years ago

1,500 Artificial increase in some greenhouses to enhance plant growth

1,000 Approximate level 100 million years ago

1,000 Common target maximum for ventilation design for buildings

405 Current atmospheric level

275 Atmospheric level before industrial revolution

190 Atmospheric level at end of last glaciation

150 All land plants and animals become extinct below this level.

This is emphasized graphically as a bar chart in Figure 7 of the analysis at http://globalclimatedrivers2.blogspot.com

I think I can see why this caught your attention. It has a certain cool factor that pumping CO2 into the ground don’t have.

Energy. The less expensive the better. Sometimes workers ask where their raise went. The power bill people. Did you not take basic math in school. More likely you voted for someone who dazzled you with magical thinking.

This appears to be a win-win situation, having nothing to do with being “green” or with climate. The CO2 in compressed form is simply acting as an industrial component, aiding in the production of oil. I had my doubts about it, but everything appears to be above board.

Financing Mega Scale Energy Projects

Further details on the challenges and details in this project.

A Case Study of the Petra Nova Carbon Capture Project

A very good way to do business!

December 4, 2008 …

The idea behind the new commercial from the Alliance for Climate Protection is that clean coal is like the emperor’s clothes: It doesn’t exist. Gore — the winner of the 2007 Nobel Peace Prize for his work on raising awareness about climate change — tells NPR’s Robert Siegel that clean coal technology is not “anywhere close to being a reality.”

http://www.npr.org/templates/story/story.php?storyId=97825453

From Shell …

Carbon capture: “the technology we cannot afford to ignore”

It’s significant and exciting. Think of the issues that currently shape our approach to the future of energy. The future of renewables is hotly debated at the moment, as is energy efficiency and how we approach nuclear power. The electrification of transport and heating are also big issues in how we think of the future of energy.

CCS is another one. Yet there is a sense that it is still to meet its potential. That needs to change. Think of all the effective international actions, policies and investment that have been rightfully put behind renewables in recent years. If the same level of effort was put into CCS, it could make a real difference.

http://www.shell.com/inside-energy/carbon-capture-the-technology-we-cannot-afford-to-ignore.html

Al Gore is a moron and generally wrong every time he flaps his gums.

Carbon capture and sequestration (CCS) only makes sense, if you intend to do something useful with the CO2, like piping it to old oil fields for enhanced recovery projects.

This is not new. Since 2000 the Dakota Gasification Company in North Dakota has been collecting CO2 from their syngas plant and piping it to the Weyburn oil field in Saskatchewan for Enhanced Oil Recovery.

The word “clean” should not appear in any of this. It is abuse of the language.

re: the use by the AUTHOR of this post the following verbiage (in more than ONE spot I might mention) “The Petra Nova carbon capture system was … ”

Shoot, I give up.

We have bought “lock, stock and barrel” into the terminology of the greens and the left …

That’s what it is. It is a carbon capture and sequestration system (CCS). It captures the CO2, post combustion. The CO2 will then be piped to an oil field to be injected for enhanced oil recovery (EOR).

The World Coal Association calls it “carbon capture”…

https://www.worldcoal.org/reducing-co2-emissions/carbon-capture-use-storage

Because that’s what its called.

Due to the pressure in the reservoir the CO2 is at supercritical conditions and becomes a solvent, that is it dissolves the oil and makes it less viscous and easy to flow. Some heavy oils are not that soluble and the asphaltenes are left behind. Supercritical extraction with CO2 is used to extract organic oils from plants and seeds.

The thing I really object to, as the expression “Clean Coal” is applied by industry to such projects, is that CO2 is being implicated as otherwise “dirty” unless captured. Rubbish.

Good point. This particular coal-fired plant was already very clean without the CCS, which does nothing to enhance its cleanliness.

As noted above, O2 from atmospheric gasses is problematic. But is it necessary to recover the CO2 separate from the other flue gasses to have the advantages of the effects of the CO2 on the viscosity of the oil? Presumably there would be little O2 in the flue gas.

“…its NOx emissions have been reduced to microscopic levels. Based on those levels, W.A. Parish could rightly claim that it is among the cleanest coal plants in the U.S.”

At long last. “Clean” here means clean. Here in Australia we still have “clean” in common usage when referring to minimal CO2 emissions. Just plain dumb, the more so when, in the same breath, “carbon” is used invariably to refer to carbon dioxide.

At long last, too, a CCS concept that aims to put the sequestered CO2 to good use. Unless and until that is demonstrably viable, CCS will remain an excruciatingly dumb idea.

David, my thanks to you for your capable education of many folks here about CCS, oil field operations, CO2 solvent injection and geology. Great job.

At the beginning of my career with CVX in Alberta I spent several years working on injection systems for an acid natural gas tertiary drive system in vertical reefs. H2S was about 13% in the injection gas, pressure was 6000 psi.

Three points to round things out for the inquisitive:

1. Separated CO2 at surface is not at atmospheric pressure. It is slightly less than wellhead pressure, say 900 psi for a 1000 psi well. Thus hard won high pressure is not wasted and the recycle compressors are much smaller.

2. Acid gas recovery systems using amines (DRS or MDEA or other) are reliable but expensive and have been used to recover CO2 and H2S in fields worldwide for decades.

3. The NRG geologists would never use CO2 injection if they were worried about the integrity of the overburden rock. So leaving CO2 in the ground is not a problem. More likely is NRG would try to sell it to someone else in the future.

Amine solvent absorption is a well known process for hydrogen sulfide removal from natural gas. Using it to remove carbonic anhydride is a natural. The one hurdle is dealing with water as this would make the process more difficult in regeneration of the amine. I’m certain an adsorber wheel type Lungstrum heat exchanger could be employed only with a four pass configuration.

Chemical engineering beats alternative energy any day.

A ijnteresting article, but I would hope that Carbon capture does not end up with politicians saying that to Save the Planet we must bury all such CO2 from any future fossell fuel power stations. This seems to be the thinking by the likes of PM Malcolm Turnbull regarding any new coal fired power stations here in Australia. We have had cases in nature where CO2 has come to the surface and killed people. .

Michael.

Ordinarily, DOE money in a clean or renewable energy project is “the kiss of death”. If this one does, indeed, turn out to be reliable and commercially viable (and I hope that it does), it will be the exception to the rule. The energy landscape is littered with the rusting remains of failed DOE energy projects.

Oil boom!

Good pun, Brian.

My first oil field summer job was for Amoco at Gregoire Lake near Fort McMurray. The field was oil sand at depth, too deep to mine. So the experimental solution was a fire flood. We pumped air down the injector wells and lit a fire. The heat and steam created by the flame front mobilized the oil so it moved to producer wells. It all worked okay until the slight slope to the reservoir caused all the completions to start sliding downhill. That and the cost of Iconel completions eventually ended the experiment.

But it was a fun summer for an engineering student.

Environmentalists used to advocate for endangered species in the amazon rain forest, pollution in china, and the like. Then, they discovered the BIG ONE. This was the mother of all causes. The solution to this problem required government intervention in the free market on an enormous scale, to the point of even completely shutting down the industrial economy. Consequently, they soon became a united army aggressively calling for the end of fossil fuel use.

Then, one day someone decided to invent carbon capture technology. Suddenly you could trap that CO2 for a much smaller cost than building renewables. But wait a minute! That doesn’t require big government!

That wasn’t supposed to happen! The fallacy!

They never thought of that before they put all their eggs into one basket!

(For the record, climate change is a hoax therefore ANY mitigation is a waste of money, but that being said it’s kind of fun to watch the big green machine squirm at the possibility of carbon capture technology becoming more viable than renewables)

Careful on the cost assumption that CCS is less capital cost than renewables. CCS typically adds 30 to 50% to the cost of a new large power plant.

Fair enough, it’s still experimental so we don’t know yet. But I’ve looked at windmills from an entrepreneur’s perspective and I think it costs about 10 times as much as coal, on the ground. Payback period is in the range of 35-45 years vs. 7-10 for coal. Therefore, it really doesn’t take much to beat renewables.

So… CO2 from coal releases oil from which CO2 subsequently is released.

If the recovered oil were left in the ground and the CO2 from the coal not captured, what would be the net difference for CO2 reaching the atmosphere?

Isn’t this CO2 exchange rather than capture, or am I missing something and perpetual motion has been invented?

This is how capitalism defeats regulatory malfeasance.

This gives you something to fuel your plane with when you go globe trotting to save the planet or golfing on somebody else’s dime.

Another nail in the coffin lid of “peak oil” . The phase of carbon dioxide in this process is supercritical. This makes it an incredible solvent, not only lowering viscosity but also penetrating pore space and liberating tight oil. Supercritical carbon dioxide is used to remove caffeine from whole coffee beans. Because carbon dioxide is an acid anhydride, it preferentially extracts this alkaloid (organic alkaline compound).

Current hard rock unconventional Petro can greatly benefit from this technology.

David,

Thanks for the Great information and follow up with replies as always. I am all for use of CO 2 to improve well production but not for sequestration without positive results. Noting that two Oxygen Molecules are sequester for every one Carbon, I suggest we call it what it is: Oxygen Sequestration which might not sound to good to many of the enviro’s and the uninformed.

A few comments from an engineer that has spent his entire career reducing emissions from coal fired power plants.

The location of this plant is ideal for CO2 sequestration. An oil field located nearby that needs a pressurized gas to extract the oil. There are a few other sites that are currently operating.

However even at this site you are not reducing CO2 but transferring it. It is being removed from the combustion gas as a gas and being compressed into the ground as a gas rather than in the atmosphere. It will be in the ground until something happens that will release it into the atmosphere. Kicking the can down the road.

The federal government has spent 100s of millions of dollars on CO2 sequestration. They have mapped out caverns in the ground that could hold the CO2. Pumping huge quantities of a gas into caverns in the earth’s core, what could go wrong with that? Well, the CO2 will find any small crack and work its way out to the atmosphere. If there a shift or fissure in the rock surrounding the cavern it would release huge amounts of CO2. CO2 is heavier than air and the gas would hug the ground filling all voids like ditches, creeks and basements. The breathable air would be displaced at those locations resulting in death of any living creature in that area.

Sequestering CO2 from coal fired power plants is technically feasible. However it takes huge amounts of power to accomplish. This makes a power plant less efficient, resulting in more fuel being burned, resulting in more CO2 emissions.

The large quantity of power consumed to remove CO2, the large capital costs to build the plant and the expensive operating costs to operate the plant makes a new coal fired plant not economically viable. Add the liability of injecting huge amounts of CO2 in caverns in the earth and coal fired plants are dead.

Delaying the release of CO2 into the atmosphere gives the biosphere more time to do it’s own sequestration thing.

There are no “caverns in the earth’s core.” Nor does CO2 sequestration entail pumping CO2 into “caverns” or anywhere near “the earth’s core.”

It involves drilling or modifying existing wells in depleted oil and gas field and pumping it into pressure-depleted porous reservoirs. The process would not exceed the fracture gradient of the rocks. The injected CO2 would be trapped by the same geologic seals as the now-depleted oil & gas reservoirs were. The injection wells would then be plugged and abandoned. So there would be zero chance of this happening:

Over time, traces amounts of CO2 may leak to the surface; however this would pose no threat to anyone.

Enhanced recovery of oil through CO2 injection has been going on since 1972. There has never been a case where a catastrophic CO2 blowout has occurred.

https://www.netl.doe.gov/file%20library/research/oil-gas/CO2_EOR_Primer.pdf

http://petrowiki.org/CO2_sequestration

https://youtu.be/OtfuYlhDjw4

Ritter, K., Shires, T.M., and Lev-On, M. 2014. Methane Emissions From Natural Gas Systems: A Comparative Assessment for Select Industry Segments. Presented at the SPE International Conference on Health, Safety, and Environment, Long Beach, California, USA, 17-19 March. SPE-168379-MS. http://dx.doi.org/10.2118/168379-MS.

CO2 is heavier than air, especially when cooled by expansion from underground compressed storage. When it leaks to the surface, it forms an oxygen-displacing bubble that suffocates animals and insects. Catastrophic blowout is not necessary to kill. Significant CO2 leaks have happened multiple times in the USA, and multiple times with Denbury Resources alone. I am not aware of any human fatalities so far due to EOR CO2, but there have been wildlife kills. http://www.ernstversusencana.ca/denbury-fined-662500-for-mississippi-blowout-of-co2-injected-in-high-pressure-enhanced-oil-recovery-so-much-carbon-dioxide-came-out-that-it-settled-in-hollows-suffocating-deer-and-other-animals. Natural CO2 blowouts and industrial accidents have killed many people. This detailed actuarial study predicts about 200 deaths per year by 2050 if large-scale CO2 sequestration is attempted (http://minh.haduong.com/files/HaDuong.ea-2011-ActuarialRiskAssessmentCCS2050.pdf).

CO2 is naturally corrosive when in contact with moisture as it forms carbonic acid which is a problem for steel pipes. Of course, the tertiary EOR process is CO2 combined with water flooding. The new injection wells are likely to be stainless steel for this reason, but all the old wells at an EOR field represent possible leak points unless they are properly located and abandoned with cement plugs. It is often more the rule than the exception that old wells are not properly documented. Turning an oil field into a sequestration site is going to be a massive job. Not doing it right is what resulted in Denbury’s leaks and fines.

Also glossed over in this article is the fact that CO2 capture saps energy from the power plant, significantly reducing its thermal efficiency. So it must burn more fossil fuel and generate more polluting emissions to generate the same amount of electricity. Sequestering carbon is actually a plan to increase the consumption rate of fossil fuels and reverses the trend of increasing the efficiency of power plants. My research indicates 65% carbon capture reduces thermal efficiency (increases heat rate) about 15%. This plant is supposed to do 90% capture, so that impact is likely the 25-30% reduction that some commenters have suggested.

A full-blown national campaign to sequester CO2 underground can only be entertained by those with no sense of the geographic scales involved, no concept of the increased polluting emissions, and no sense of the substantial immediate mortality risks compared to the imperceptible and distant climate benefit that is still only based only on falsified climate models.

Blowouts are rare; but they do happen. A $650k fine is trivial. Nor is it pertinent to CO2 sequestered in a properly abandoned oil field.

Predictions of x number of deaths are as worthless as the EPA’s claim that the CPP will prevent 90,000 asthma attacks per year.

In this specific case, the CCS will only affect 10% of the generation station’s coal capacity and it will lead to the production of 60 million barrels of oil, which would otherwise be stranded.

You are correct that the scale of sequestration above and beyond EOR is huge and that the mythical threat of CAGW does not justify the cost.

Super-critical CO2 at 1000 PSI / 74 bar has less than 1/4th the CO2 per unit of volume as as crude oil, so it requires more than 4 times the volume to sequester the same amount of carbon back into the ground as is vacated in producing the oil containing it. So we know before we begin that this is a dead end for the volumes needed for climate change purposes. The alternative plan has become injecting CO2 in to deep saline aquifers. For either of these options, stimulating earthquakes is going to be an issue. Not because pressures exceed the fracture gradient of rocks, but for the same reasons as reinjected fracking disposal water is linked to them — because water is a lubricant, and because it is chemically active in such reactions as serpentinization at depth, that change rock density.

Roger that. There is no climate-related justification for CCS.

But, if a little bit of CCS can enable coal-fired plants to remain in service longer, operate at a higher capacity and help recover some of the 85 billion bbl of oil recoverable through CO2 EOR… It’s a good thing.

Regarding injection wells, the rocks are already saturated with brine before wastewater is injected. The injection wells do increase the pore pressure and this can trigger induced seismicity. The fix for this is to carefully site injection wells where they are sufficiently distant from faults and to manage the pore pressures more carefully.

..You claim to be an engineer, yet, you do not know the definition of the Earth’s core ??

Did someone kidnap and replace seaice1? This version is managing to make sense.

http://breakingenergy.com/2017/04/18/bipartisan-support-grows-carbon-capture/

What’s the quote about bad ideas made even worse through bi-partisan politics?

The last time 99 Senators agreed on something, we got the TSA.

David, your information is true for the sites that use the CO2 to force out oil. However as I stated earlier those sites are unique and there are not a lot of them located near coal fired plants. Department of Energy initiated a program to identify and map caverns throughout the United States to accept injection of CO2 for storage. They called them deep geological formations. They have assigned risk with each area. I personally worked on these projects. These caverns would be used to store removed high pressure CO2 that would be pumped into them.

I worked on a potential coal fired plant that used their proximity to one of the caverns as a potential for the plant to install CO2 sequestration at a future date. Unfortunately the plant was never built, too expensive. For additional reading go to:

https://www.netl.doe.gov/research/coal/carbon-storage/atlasv

The word “cavern” doesn’t appear anywhere in the document because CCS has nothing to do with caverns. DOE put together an atlas of geological formations suitable to be CO2 sequestration reservoirs:

https://www.netl.doe.gov/research/coal/carbon-storage/atlasv

These are formations which are porous, permeable and sealed by impermeable overburden.

Provided care was taken to not exceed the fracture gradient when operating the injection wells, there is absolutely no chance of the sort of catastrophic blowout you described.

Here’s the link to the full atlas…

https://www.netl.doe.gov/File%20Library/Research/Coal/carbon-storage/atlasv/ATLAS-V-2015.pdf

?w=680

?w=680

I would imagine that even if cracks did form, and even if these cracks did make it all the way to the surface, all that would happen would be a very slow seepage of CO2 into the atmosphere. Slow enough that even sensitive instruments would have trouble detecting it.

And that would be a worst case scenario.

That’s a SyFy channel scenario.

Another consideration is the huge quantity of CO2 produced by a medium sized coal fired power plant. A 500 MW plant burning an eastern bituminous coal with a 80% capacity factor will produce approximately 880,000 lb/hr of CO2. That is 3,850,000 tons per year. A typical coal fired plant is designed to operate for 25 years, however most operate for 35 years plus. That will take a big user of CO2 or a big storage area for a long period of time. Again it would not be broadly feasible for coal fired plants.

The shear volume of CO2 and the economics are definitely obstacles for CCS.

..No wonder the green plants are so happy !!

David, I guess I used old terminology when using caverns. I looked back at notes and early in the development of the CCS by DOE the word cavern was used. I may have been stuck using old terminology. There was an early design to freeze the liquid compressed CO2 in a large missile shaped device with a heavy tip. Ship the container by rail to be loaded on to barges to be dropped into the ocean. The high pressures and low temperatures of the deep ocean would not allow the CO2 to escape. I guess that is where my concern for dumping things in the ocean or pumping something into the ground that is not my naturally there. Unintended consequences.

That’s not “old terminology.” Caverns are large underground caves. No one would ever even think of trying to store gas in a cavern, with the exception of salt domes.

CCS has always entailed drilling injection wells into porous and permeable rocks that are sealed off with an impermeable overburden. Porous and permeable rocks have never been called caverns.

David,

When I read the discussion I kind of recalled mention of Salt Caverns for natural gas storage in NJ.

I am not a geologist nor do I have anywhere the wealth of knowledge you have about the subject but googled the subject and found the following FYI which may not be relevant to the discussion.

Thanks for sharing your knowledge via WUWT.

htps://www.eia.gov/naturalgas/storage/basics/